Why does your impact wrench feel like it’s not impacting?

Why the impact wrench cannot remove lug nuts easily?

What’s wrong with it that’s causing it to feel too weak or like it isn’t getting the job done properly?

What is Impacting On An Impact Wrench?

In the simplest words I can think of, “impacting” in the context of impact wrenches refers to the procedure through which these tools perform lots of high-torque impacts or hits to the nuts or bolts you use them on.

Let me get into a bit more detail for those interested.

A motor generates enough force to quickly move the “hammer“.

This “hammer” collides with the anvil of the tool, which results in a rapid, high-torque impact outputs.

That fast and strong impact is outputted through the socket to the fastener, delivering a lot of torque super quickly.

This happens many times each passing minute, and is what makes the impact wrench so strong and “impactful.

Read:

Impact Wrench Not Impacting

Now that you know what impacting is specifically, and what components are involved in it, it’ll be a lot easier to understand what could be wrong.

Let’s start with one of the most common possibilities.

- Loose or Damaged Anvil

It’s important to make sure your anvil is in perfect condition while using an impact wrench.

If it’s too large or small compared to the sockets you’re trying to use it with, it won’t work.

Using wrong size of sockets on the impact wrench would make it difficult to be attached or detached.

Plus, a damaged anvil won’t be able to transfer the force required for impacting properly, which is why you could feel your tool isn’t impacting.

Sometimes the impact wrench would even jam and not able to rotate at all!

This is what the anvil is on your impact wrench, my video below will show you how to change it if it is damaged.

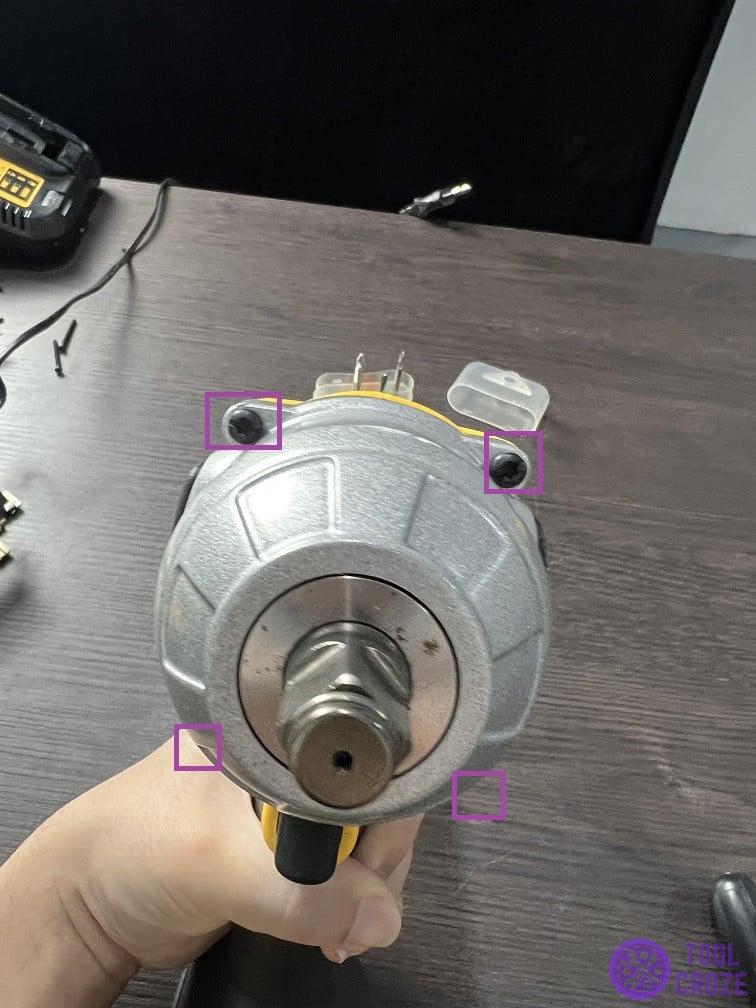

As you can see in the image below, my impact wrench anvil is clean, not visibly damaged in any way, and in top condition. You should always keep yours looking the same way.

I highly taking good care of this component. Even if there’s no damage, the right size itself is so important.

For example, the wrong size can get in the way of loose anvil retention.

This is important because it keeps the anvil stable and helps deal with the friction put on this component.

- Battery Issues (Cordless Model)

This next problem I want to talk about is for people that have cordless impact wrenches like mine (DeWALT cordless impact wrench)

My impact wrench works on a rechargeable battery, as seen below, which can be pretty convenient since you can use it anywhere.

But, it’s less convenient when there’s not enough charge inside the battery.

Whenever I try to use the impact wrench with a low battery, I’ve noticed that it loses its impact a lot.

Besides, you would also feel that impact wrench is weaker and not strong enough.

I would suggest you to fully charge your impact wrench battery before use.

Besides, the battery might not holding charge or not charging at all and no light if it not healthy anymore.

Or it simply won’t charge anymore and provide no power to the impact wrench.

In this case, follow my video instructions below to get it resetted.

Besides, I would also suggest you to measure the voltage of your DeWALT battery as shown in my video below.

- Impact Mechanism Malfunction

Earlier, I mentioned all the different components involved in impacting.

If any of these components get damaged, the whole procedure can be ruined.

Start with the hammer and anvil pins.

Make absolutely sure that these aren’t loose or damaged.

It’s possible for them to get rusty or stiff after lots of use.

I recommend making sure that the hammer can always rotate freely to generate the right torque for impacting.

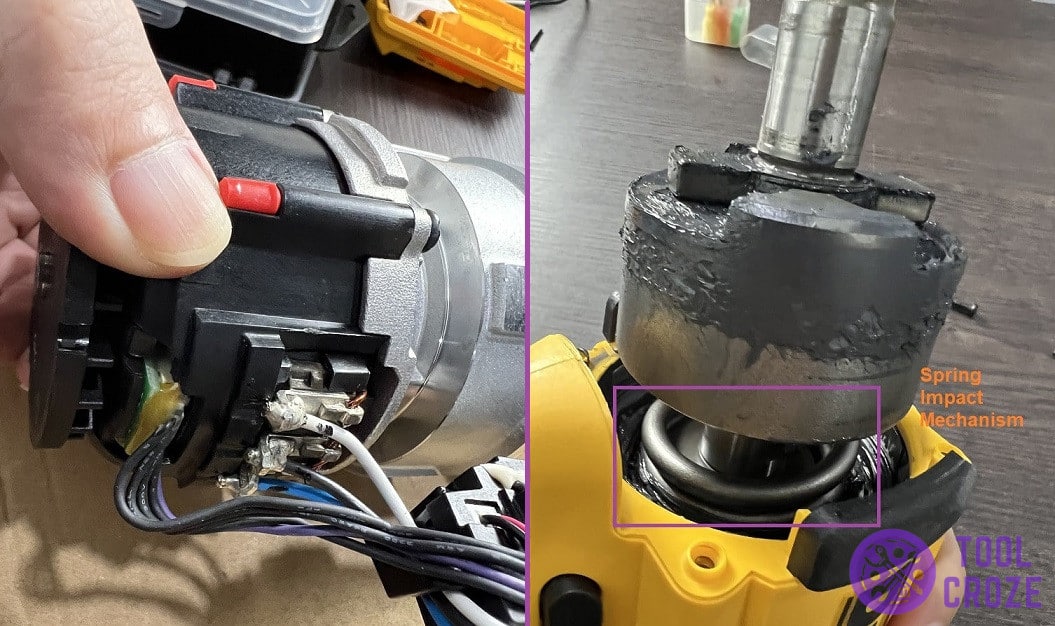

Another thing I want you to look out for is the spring impact mechanism, which you can see from the image below.

It’s a component on some impact wrenches, like mine, that lets the anvil move forward and back slightly.

It helps generate the right force needed for the job to get done.

Speaking of the anvil, one thing you should do is to tighten its screws.

It might be too loose and not generating enough power for the right impact required.

I recommend tightening these screws I’ve highlighted below.

I regularly tighten these if necessary so my impacts stay effective and my tool’s anvil stays in place.

Also, this can prevent the impact wrench grease leaking out issue.

- In Reverse Direction

This problem could be because of something silly, like you using the wrong direction setting.

This has happened to me, and it was a funny oversight that I’m sure others might make sometimes too.

So, don’t make the same mistake as me and always remember to check this switch, which is responsible for the direction your impact wrench swings in.

If it is going in the wrong direction, it won’t have the right kind of impact to do the job you want it to do.

Also, if you set it to the center, the impact wrench is locked and not able to spin at all.

It might give you false impression that the trigger on impact wrench is problematic, but this is completely normal.

- Motor Issue

One last component from my explanation that I haven’t talked about yet is the motor, which is also super important.

It’s responsible for generating the force behind the tool’s impacts, so any issues with it will obviously result in weaker impacting.

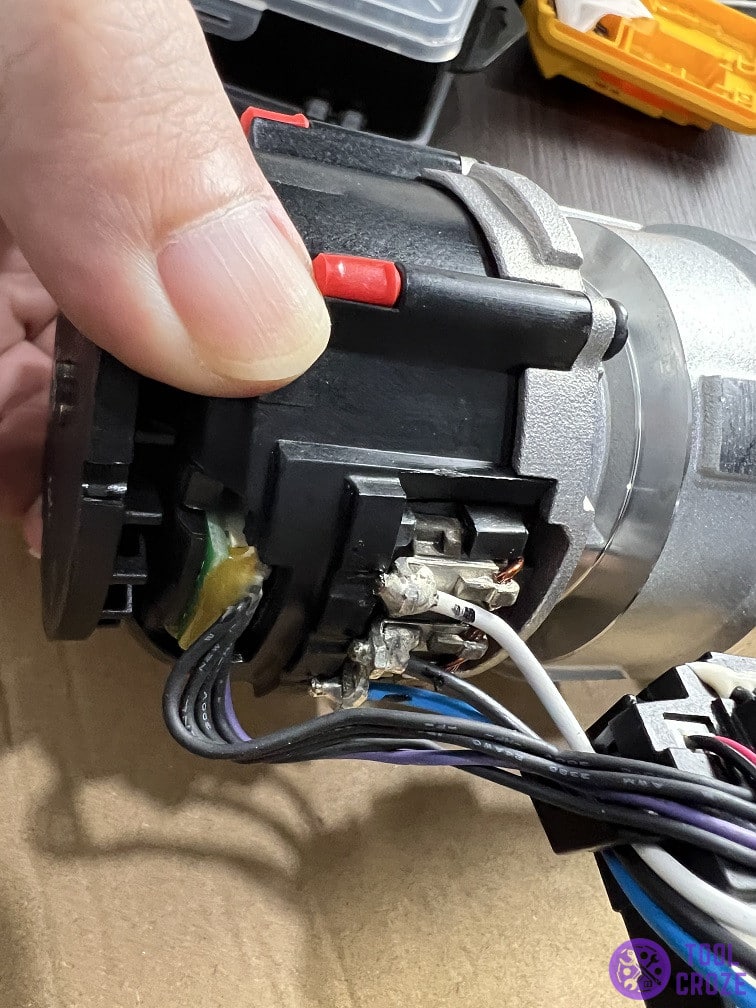

I took the covers off my impact wrench to show you what the motor looks like.

It’s complicated and has some complex wiring, but issues with it aren’t too hard to fix.

One thing I suggest is to check for loose parts around or inside the motor’s assembly.

This could result in low impact generation or the impact wrench won’t spin issue.

Other than that, worn out bearings can also hinder impacting, because they reduce the efficiency of the motor.

If the bearings are loose are damaged, I suggest dealing with them as soon as possible.

Besides, is the impact wrench getting hot easily after use?

I’d recommend checking to see if any of the wiring around the motor is damaged.

As you can see from the image below, there are multiple wires connected to the impact wrench motor.

Make sure all these wires are connected securely to the impact wrench motor.