I find it pretty annoying how my DeWalt impact wrench decides its not turning sometimes, and doesn’t budge until I troubleshoot it.

So, I thought a lot of other people might find this annoying too, which is why I wanted to share the main solutions that help me when this happens.

Read: Use Impact Wrench To Tighten Lug Nuts, Why & Why Not

DeWalt Impact Wrench Not Turning

- Battery Issue

Personally, the main cause of this problem has been the battery.

For example, low battery life causing the impact wrench to have little power and not turn properly.

Besides, it might also make the impact wrench not “impacting” enough.

Even now the battery’s off, so I decided to take this photo. Remember to keep your batteries charged up.

Besides, to make sure the DeWALT battery is healthy and provide correct voltage, you can use a multimeter to check the voltage as shown in the video below.

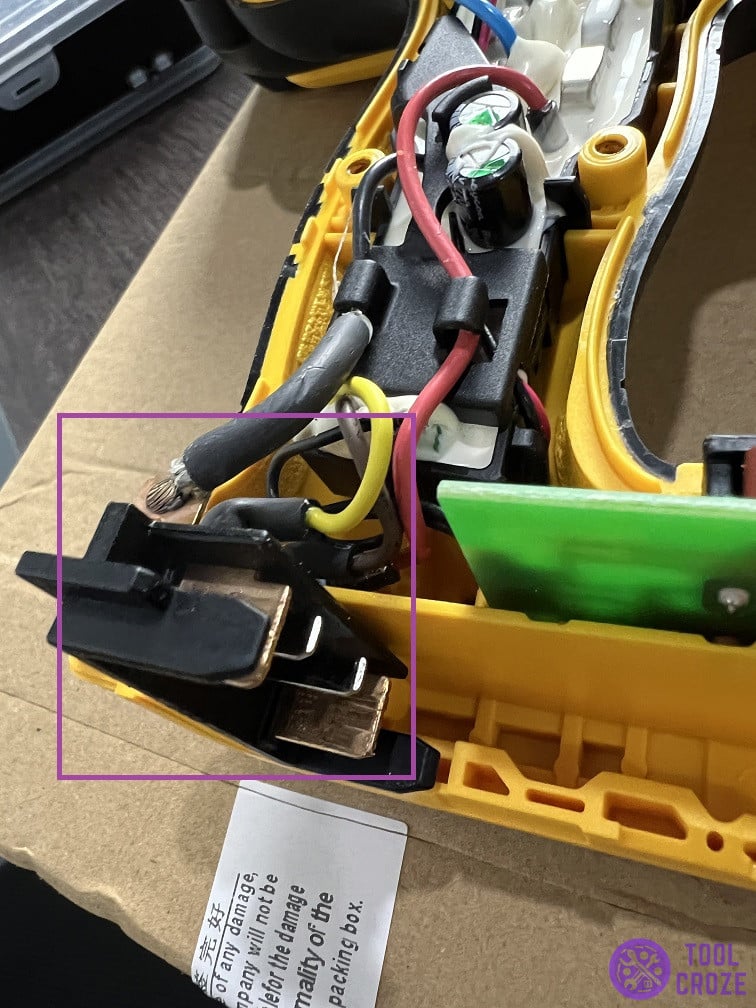

For DeWalt impact wrench users specifically, I advise keeping the charging contacts clean.

These pins and slots on your charger and battery are highly important, because they’re responsible for the transfer of power.

If these aren’t clean or get damaged, the impact wrench won’t transfer power properly. Here’s what the pins look like on my device.

Even if nothing looks evidently wrong with the battery, I recommend using another DeWalt battery to power your impact wrench.

It’s a safe way to confirm if the issue really lies with charge or there is any DeWALT charger issue.

Get a fully charged battery like this to avoid any torque/speed issue on the DeWALT impact wrench.

If your battery is having charging issue, you may view the video below to troubleshoot.

- Faulty Trigger Switch

You need to press a trigger on the impact wrench to get it to spin.

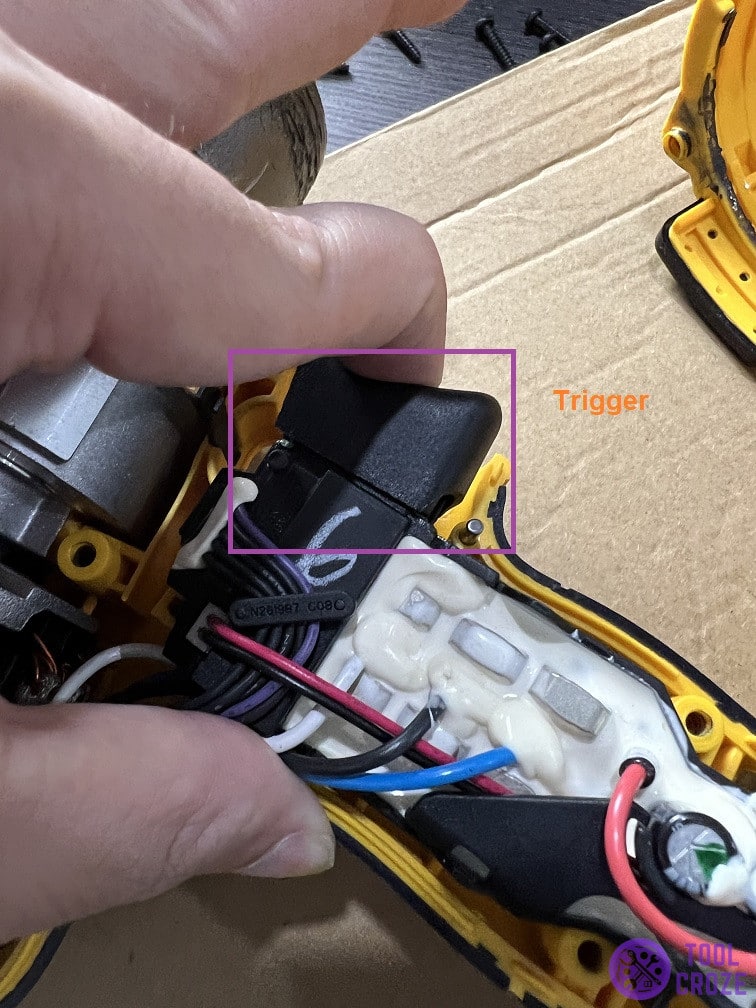

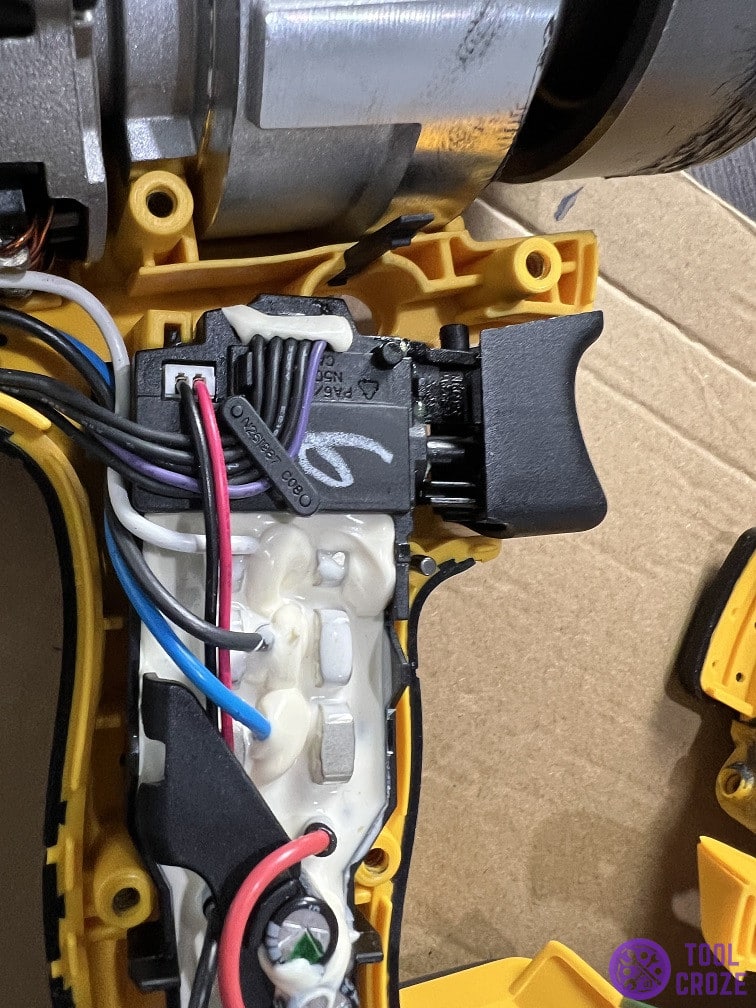

I put an image below of what that trigger looks like. If it’s not functional, then the impact wrench won’t spin around.

One thing that helps me is to press it as hard as I can.

That pushes it in, and knocks away any debris if it’s blocking the trigger from being properly pressed.

But, if it wasn’t that easy for you, I suggest taking the cover off your device and giving it a closer look.

Make sure that none of the wiring around this component is loose or noticeably worn out.

I recommend looking out for any potential debris or dirt stuck around it too.

After removing the cover, I press the trigger repeatedly to just 100% confirm that it’s pressing properly.

If you suspect the impact wrench trigger is not working, read this post.

One symptom of jammed trigger is that the LED light on impact wrench might not turning off automatically.

- Motor Problems

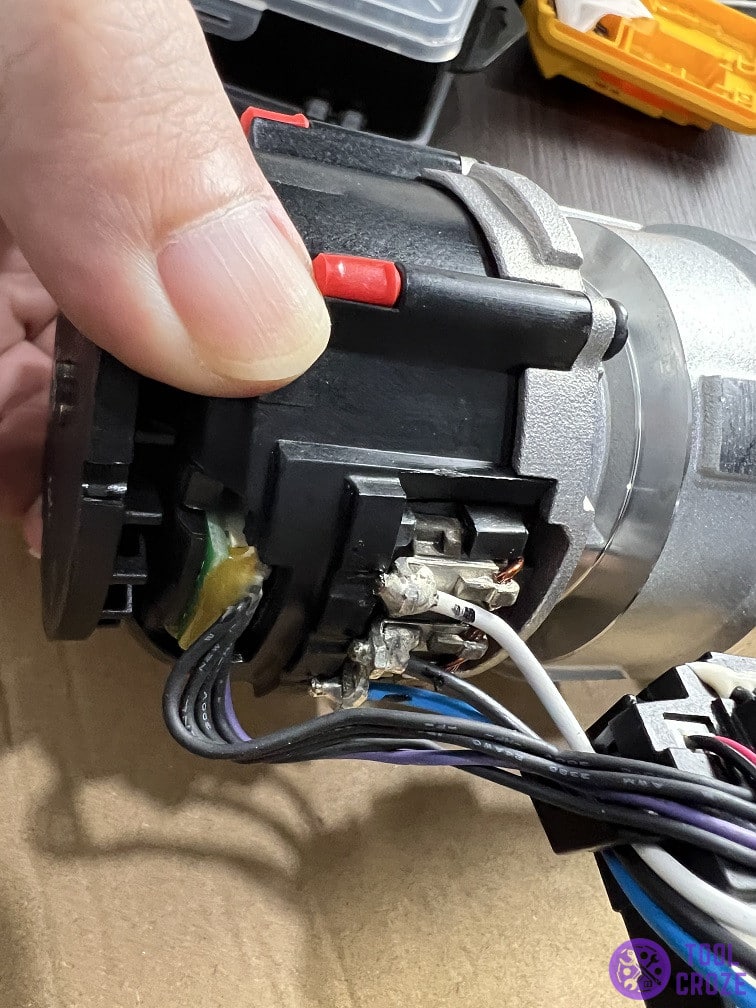

The motor on your impact wrench is responsible for generating the force the device needs to work.

Without that force, it’s not much use.

That’s why any motor problems could result in weaker impact wrench output, and your DeWalt impact wrench won’t spin.

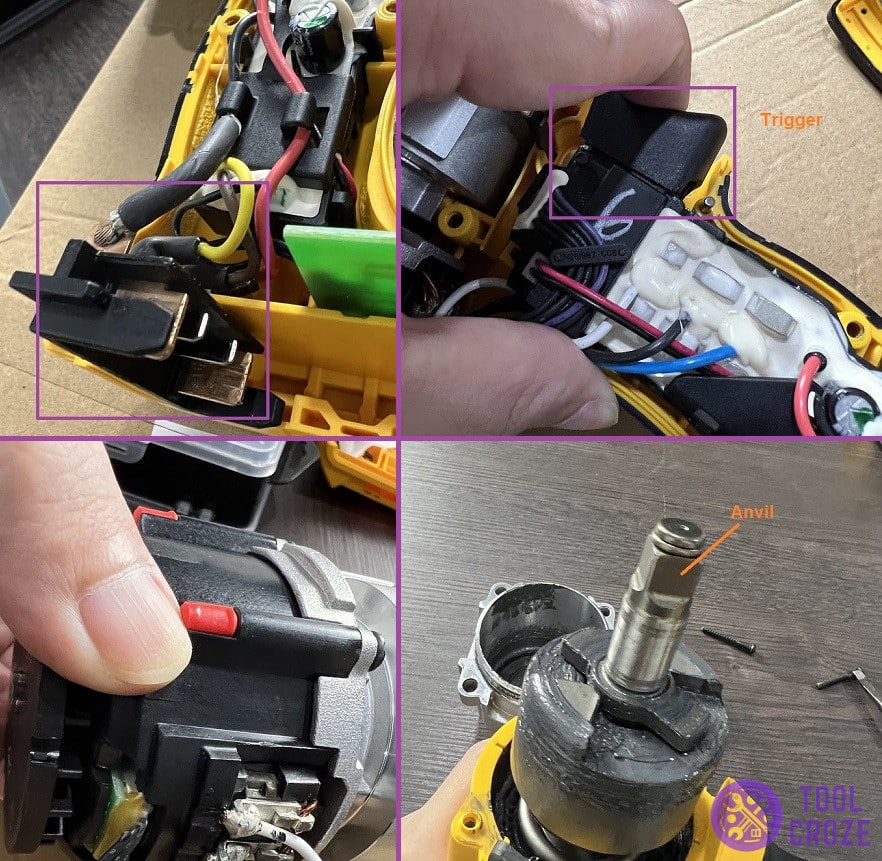

So, get the cover off the device and expose the motor the way I have in this image.

Once you do that, use a multimeter to confirm whether or not the motor is drawing the power it needs.

Take a close look at the wiring too, and see if it mostly matches mine from the photo above.

Make sure there aren’t loose wires, or that there’s no burning smells around the motor as they signal overheating.

- Loosen or Jammed Anvil

A loose anvil won’t be able to provide the impact wrench with the torque it needs to turn effectively. If you aren’t familiar, I took this photo to show what the anvil looks like.

- Check if anvil is securely attached

- Check for any foreign objects lodged in the anvil.

Make sure that this thing is properly attached to your impact wrench.

It needs exact placement to work the way it’s supposed to, so ensure it isn’t loose.

Additionally, make sure there’s no debris around it to avoid impact wrench jamming issue.

Here’s my video to demo how to open the anvil cover and get it replaced.

That’ll cause problems like you might not be able to remove lug nuts as it won’t be able to move back and forth properly.

- Overheating

As a failsafe, DeWalt impact wrenches stop working when they go beyond a specific temperature.

This is to prevent any permanent damage from overheating.

All I have to say for this particular possibility is that you should give the device room to cool off.

I always avoid too much use consecutively, and you should do the same.

- Lack of Lubrication

The anvil rapidly moves around forward and back. To do this, it needs proper space and a smooth environment.

If it doesn’t have that, it’ll get slower, and that’ll stop the impact wrench from turning properly.

The point of my thoughts is that you should grease up the area around the anvil to let it move properly.

Make sure not to over lubricate it to avoid grease leaking on the impact wrench.

Check the part of the device that I highlighted in the image below and ensure that it’s greased well enough for proper movement.

- Damaged Gearbox

I’ve found the gearbox being a likely culprit for problems like this, because it’s so sensitive.

That’s why I think it’s worth checking out if the other tips didn’t help so far although it might not be the common DeWALT impact wrench issues.

The gears are pretty close to where the motor is, as you can see in this photo I took. So, take the cover off and start inspecting them.

All you have to do really is to just see if there’s any visible wear or hinderance near the gearbox or inside it.

You could also move the gears around with your hands or using some tools to see if they move without any setbacks.

- Faulty Electronics

Like any machinery, DeWalt impact wrenches are pretty fragile. They depend on many little wires, and any damage to these wires can get in the way of performance.

At this point, the problem could lie anywhere, so I suggest giving everything a close look.

Start by taking the cover off and inspecting the main wires you can see. If everything seems fine with them, look around for smaller wires inside components. There could be an issue with those.

Furthermore, I use multimeters on all the circuit boards to see if they have power. If any circuit board isn’t drawing power, that means there’s an issue with that part of the device that I need to fix.

- Foreign Object

This is something I’ve mentioned plenty of times already in this article, so you know by now that debris and dirt are things to avoid in your impact wrench.

With that said, my final suggestion it make sure there’s neither of those in your device.

Any foreign objects can cause problems with electronics, as they work on delicate procedures that can get interrupted.

I always keep my DeWalt impact wrench in its casing when I’m not using it, and I highly suggest you do the same.

It keeps it safe and as good as new until the next time I need to use it.