It’s really limiting when the speed control feature is not working on an impact wrench, because it might stops you from completing specific tasks.

Without proper speed setting, you might feel that the impact wrench is not strong enough or the tool can’t provide enough impact force.

What Is Speed Control For?

I doubt anyone who’s used impact wrenches before doesn’t know what speed controls are.

As the name suggests, it’s something that can be used to change the speed settings on the impact wrench.

For example, my impact wrench has a little knob I can push or pull to change it to higher or lower settings.

These make the device work with more force and speed for jobs that require a bigger workload.

Read: Common DeWALT Impact Wrench Problems

Impact Wrench Speed Control Not Working

- Faulty Speed Control Switch

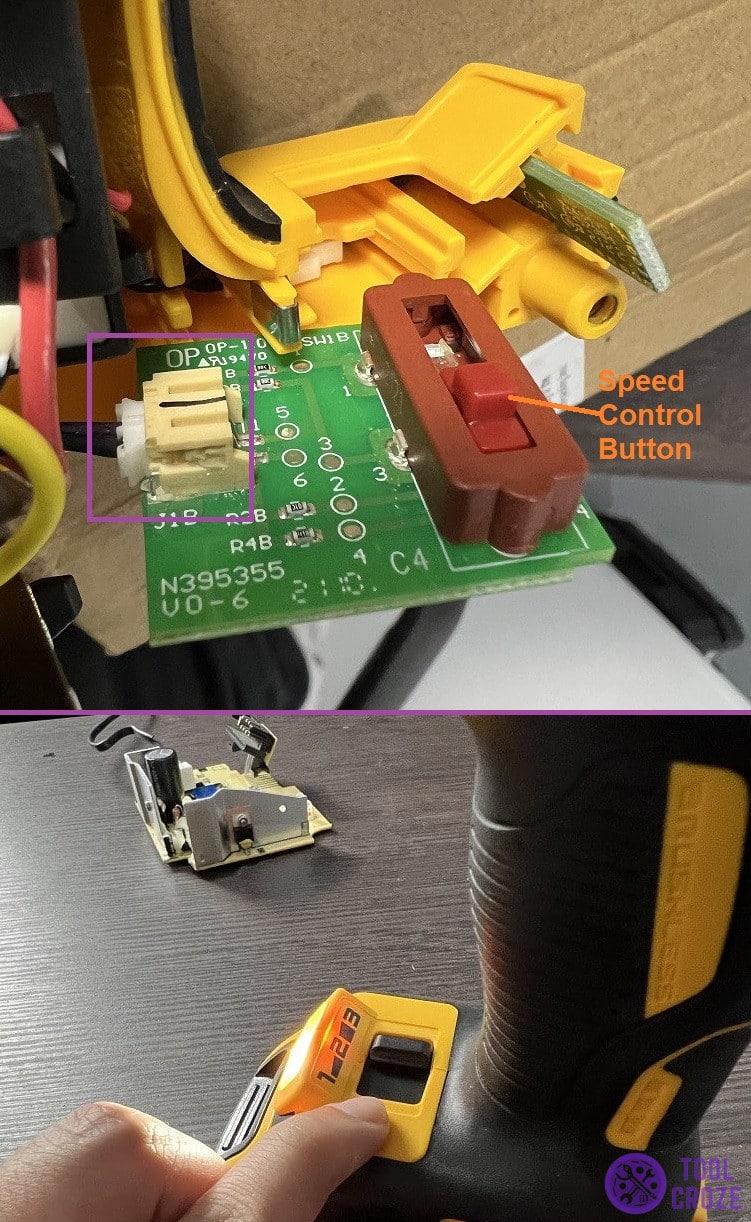

As I mentioned just a bit ago, my impact wrench has a little knob that controls the speed on it.

You can see it in the photo below.

If something is wrong with this little knob or the mechanism that it works around, then the speed controls obviously won’t work.

There can be a couple of different issues like making the impact wrench not to spin.

For example, there’s the possibility of wiring problems around the switch that make it impossible for the device to know when you change the speed setting.

This can happen if there’s a faulty circuit board or damaged wiring.

When the knob turns, it goes through small sections that let the device differentiate between the different speed levels.

If there’s an issue with these sections, or something else that makes it so the impact wrench can’t separate them from each other, speed controls won’t work.

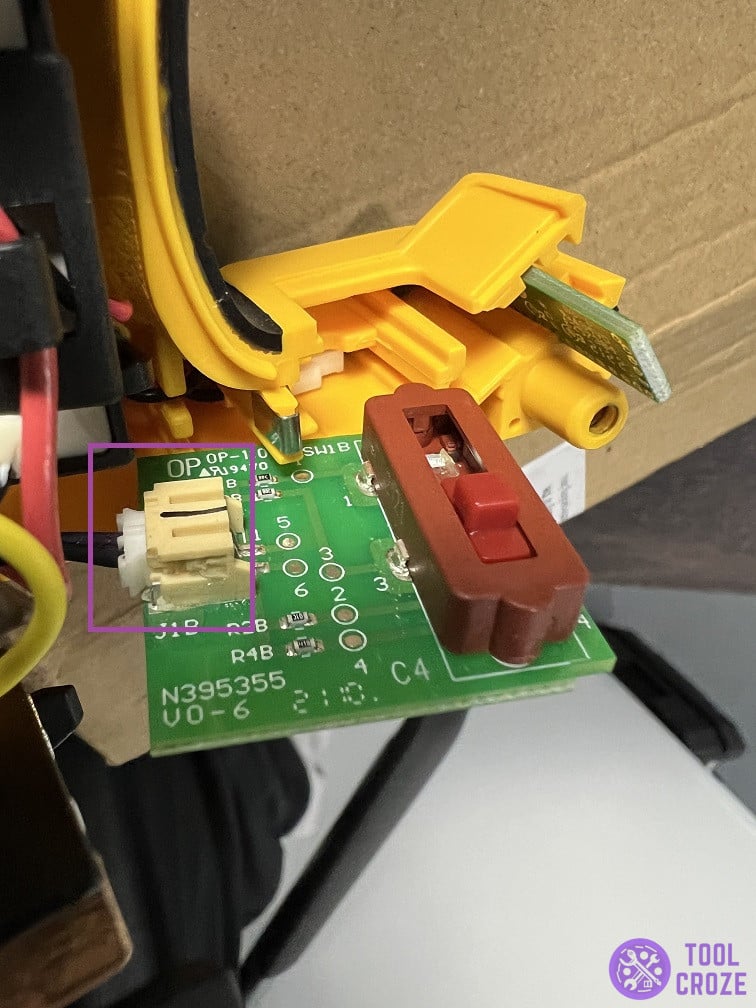

As shown in the image above, there is a “Quick Connector” that connect to the speed control board.

Simply disconnect and reconnect it back, sometimes this trick will solve the wire connection problem.

- Electronic Malfunction

A simple electronic problem could be the reason behind your issues.

This can be something as little as water or moisture seeping into the device and causing problems with wiring or circuit boards.

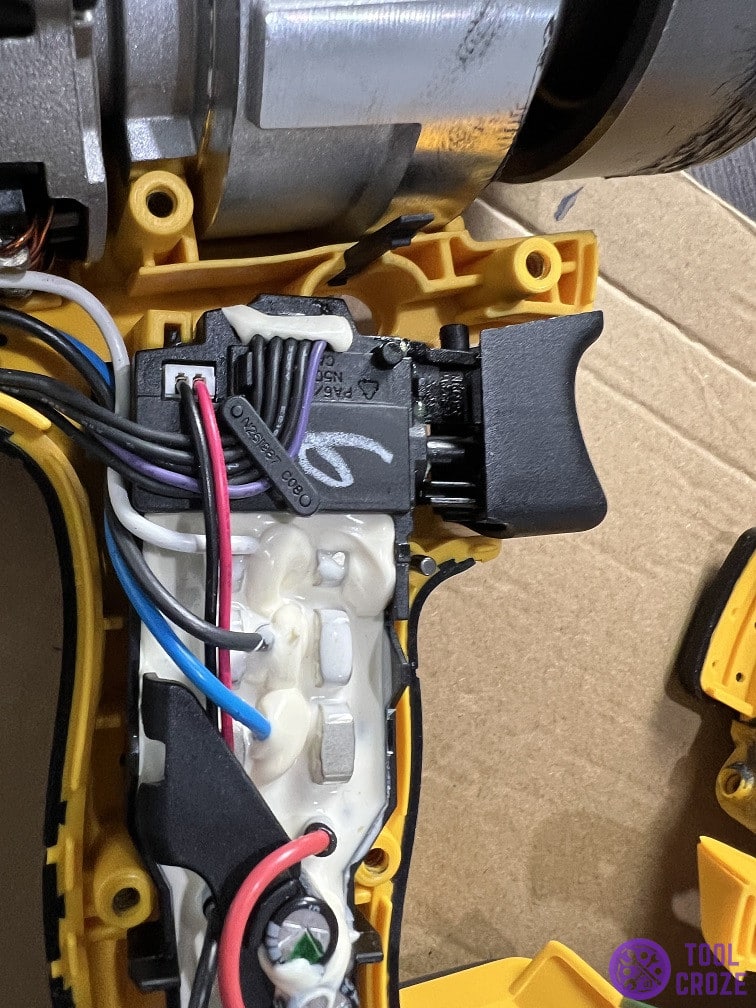

I took this photo to show how my wires and the inside of the device in general look completely dry.

Yours should be this way too, and always kept away from moisture.

Overheating can also cause damage to circuit boards and cause malfunctioning in the device.

As shown in the image above, there are “white gel” surrounding the electronic board.

I am not sure what are those gel but I think it is some kinds of insulator or help to keep the electronic board cold.

Carefully smell and inspect the device’s interior for any burning smell to confirm whether or not that’s the reason why this is happening.

- Motor Issue

The motor on an impact wrench is what generates the speed and strength. If it doesn’t have full functionality, neither will the rest of the device.

For example, a worn out or overheated impact wrench motor won’t be able to work to the machine’s full potential, it might not be able to remove lug nuts, etc.

This means that if you’re using a worn out motor at level 3 speed control, it’s the same as using a perfect motor at level 1.

That’s why you can’t tell the difference between the different speed control levels, as the motor isn’t working right.

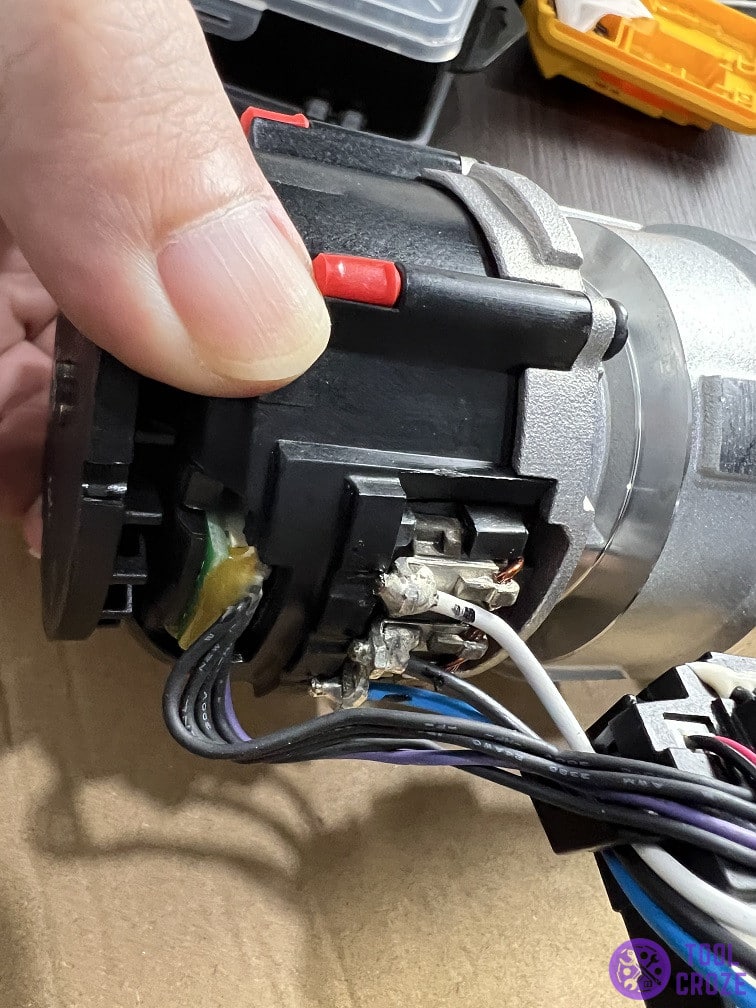

If the motor gets its wiring damaged, overheats, or gets slower because of debris, you’ll notice worse performance.

It could also happen after a few years of using the same impact wrench.

As you can see from the image above, there are 3 wires (Blue, Black and White) soldered to the motor of my impact wrench, make sure these wires are connected securely.

- Weak Battery (Cordless Model)

I have a wireless impact wrench, and this last solution is for others like me.

It’s important to remember that your device is only as powerful as the battery that charges it.

If the battery is low on charge, the performance will start suffering too.

Not enough battery could mean the device is having a problem reaching higher speeds, because there’s not enough power for it.

Here’s my video demo how to measure the voltage of DeWALT battery to make sure it is in good condition.

Make sure you’re not trying to run your impact wrench like my empty battery here.

Try to press the battery indicator to check if it is working or not.

Recharge the battery fully and see if that helps the speed controls come back to life.

If the battery won’t charge, you might need learn how to reset it by following the video below.