Multi-purpose equipment like DeWALT’s oscillating tool is great to have around. It helps with so much, since it can cut, sand, scrape, and do much more. But, it won’t do any of that if it can’t oscillate.

But, what makes it so that a DeWALT oscillating tool is not oscillating and cutting anymore? Well, there are a few obvious things, and a few technical ones. You can check them all out in the list below!

DeWALT Oscillating Tool Not Oscillating and Cutting – 4 Fixes

- Incompatible Blade

I have an important question before I say anything else. Do you hear the tool when pressing the trigger? Does everything seem to be working fine except for the blade not oscillating?

If everything seems that way, I think you might just be using a blade that isn’t compatible with your DeWALT oscillating tool. When doing so, the gear won’t work right, leading to issues with movement.

Only use blades that are compatible with the tool, and the right size for it. Otherwise, the whole thing won’t work right. Personally, I use the official ones from DeWALT, which you can see below.

If you’re using a blade that’s compatible, ensure that you put it on the right way. It should be well adjusted with the lever, and have no issues connecting to the gear either.

Any problems like that translate to issues with oscillation. Other than their impact on performance it’s also not safe to use loose blades, so that’s another thing to watch out for.

In case you really need to change the blade on your DeWALT oscillating tool, I have made a video which shows how you can do that. You can watch it below.

If you are using the “DeWALT style” blade, you just press the holder to release and install the new blade.

For the universal type of blade, you can’t use the clip, so you need to use a DeWALT oscillating tool adapter to install the universal blade. First, you would need a HEX key and then install the blade as shown in the video.

I also have a video about how you can use the DeWALT oscillating tool universal adapter. You can watch it below.

As mentioned earlier, you would need a Hex key in order to use it. Use the Hex key to install the universal blade with the adapter as shown in the video.

- Damaged Gear on Head of Tool

The gear is what connects to the blade of your DeWALT oscillating tool and controls its movements. But, without a functioning gear, the blade won’t move right anymore, leading to no oscillation.

It’s actually not uncommon for this to happen. The gear has to handle a lot of pressure regularly, and the impacts from the blade constantly coming into contact with hard surfaces also affect it.

That’s why eventually, the gear on the head of your tool will start wearing down. Eventually, it’ll get to the point where it’s no longer functional, and you need a new one instead.

Most likely it’s just regular use that damaged its surface. That kind of damage affects how it holds the blade. After a couple of users of heavy use, getting a gear replacement is inevitable.

Put a new gear on the tool to get it oscillating and cutting better than ever again. That will fix the problems with its movements, and you shouldn’t encounter this any longer.

- Faulty Motor Inside Oscillating Tool

Oscillating tools need a lot of force in order to do all the different tasks they’re capable of. Without a motor to provide that sort of force, it obviously won’t work the way users want it to.

What I’m trying to say is; maybe your DeWALT is having trouble because the motor gave out. It can only generate torque for so long before it starts going bad, and that may be what’s happening to yours.

It’s another normal part of a power tool’s life cycle, and something that will inevitably pop up after some time.

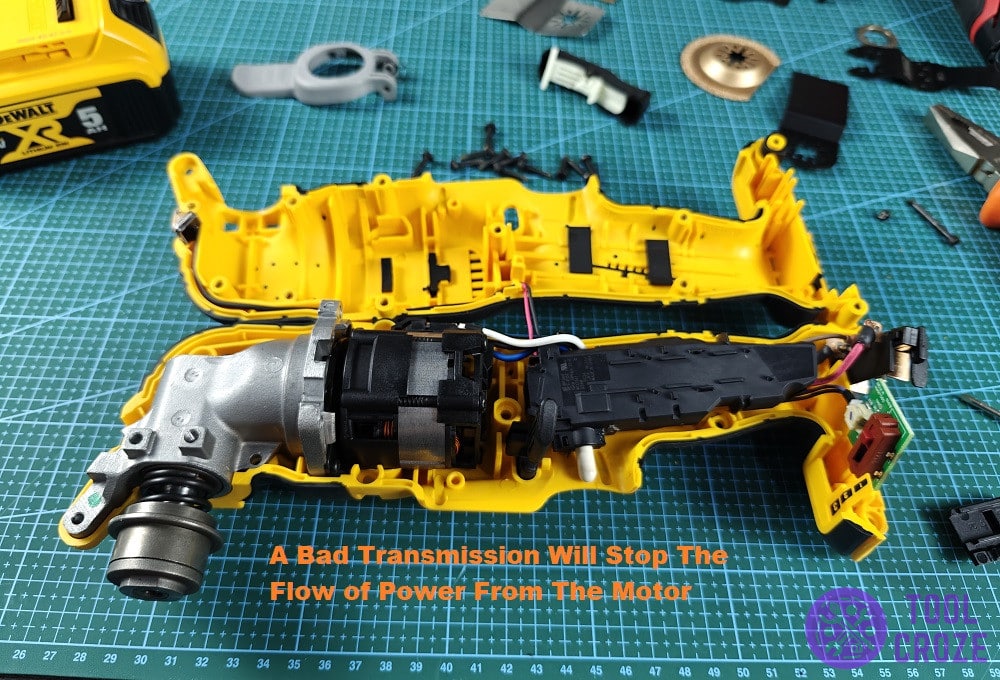

Remove the covers from the DeWALT oscillating tool to get a look at the motor, the same way I’ve done it in the photo above. Now, what you have to do is use a multimeter on this component.

Multimeters will let users know just how much voltage the motor is generating. Depending on how normal or low that is, it will decide what you should do next.

In case the voltage is too low and the motor obviously can’t function any longer, you’ll need a replacement for it. Motors don’t cost anywhere near as much as the whole tool does, fortunately.

The only hard part is swapping the current motor out with the new one properly. I suggest following a tutorial or getting someone more experienced to do it instead of trying this yourself.

- The Transmission is Shot

Did the voltages on the motor show up normal? If so, that probably means something’s wrong with the transmission instead. It’s not transferring power from the motor to the rest of the tool.

Dealing with the transmission is a lot more expensive than it is dealing with the motor. At that point, it’s almost equal to the cost of buying a whole new DeWALT oscillating tool.

Buying a whole new DeWALT oscillating tool is exactly what I suggest because of that fact. Buying a new tool is much better because of much longer it’ll last you than a repaired one.

While repairs are certainly possible, it makes no sense to get them in this case. On top of being much better, a new DeWALT oscillating tool will come with a warranty and a much better condition.

Hi,

Thanks for the article, this week my multitool suddenly stopped oscillating with an unpleasant crucnch sound, after a run of heavy cutting, it’s been in service since 2017 so quite old, any ideas on what component would’ve failed?