Every tool has its ups and downs. DeWALT’s oscillating tool is no exception to that fact. If you look online (which you’re doing right now), you’ll see a bunch of other people struggling with theirs.

Based on their experiences, and even mine, I made a list of ways to troubleshoot common DeWALT oscillating tool problems. It might have what you’re struggling with, and some tips that’ll help in the future!

But before you read the rest of this article, I suggest you first watch the short video I made about what can you do when the DeWALT oscillating tool is not working or facing issue like it is not oscillating.

On this video, I have summarized the common problems of the deWALT oscillating tool like a battery related problem, a jammed trigger, a motor related problem, and a LED problem.

Troubleshooting 4 Common DeWALT Oscillating Tool Problems

- Drywall Dust Clogging It Up

Clogging is a big, big problem for power tools. The reason why I’m saying that is because of the nature of this tool’s use. An oscillating tool is going to come across drywall A LOT.

Anyone that works around it often knows just why drywall can be such an issue. But, for those that don’t, it’s because of how easily drywall dust seeps into crevices. It’s a big cause for clogging in tools.

Drywall dust can cause a bunch of problems once it’s inside. A tiny bit won’t give users too much trouble. After it starts building up, though, it might stop the tool’s movement altogether.

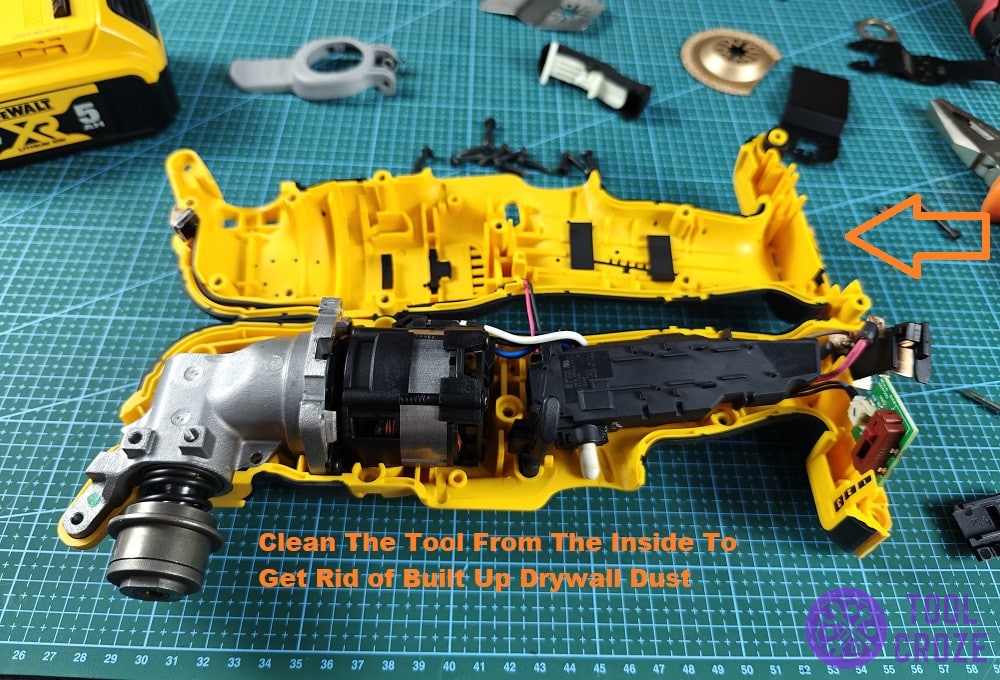

It can get in the way of the motor, the gears, and more. In short, it can make the tool stop functioning properly. So, open your DeWALT oscillating tool like I have in this photo, and give it a good look.

Does it look dirty inside? I recommend using some compressed air. Blow it all across the corners and crevices of your DeWALT oscillating tool to root out drywall dust and clean things up!

While you’re at it and the covers are open, I recommend giving any wires and connections between the components a look as well. If any are loose, that might also stop movement and functioning.

- Lever Broke Off

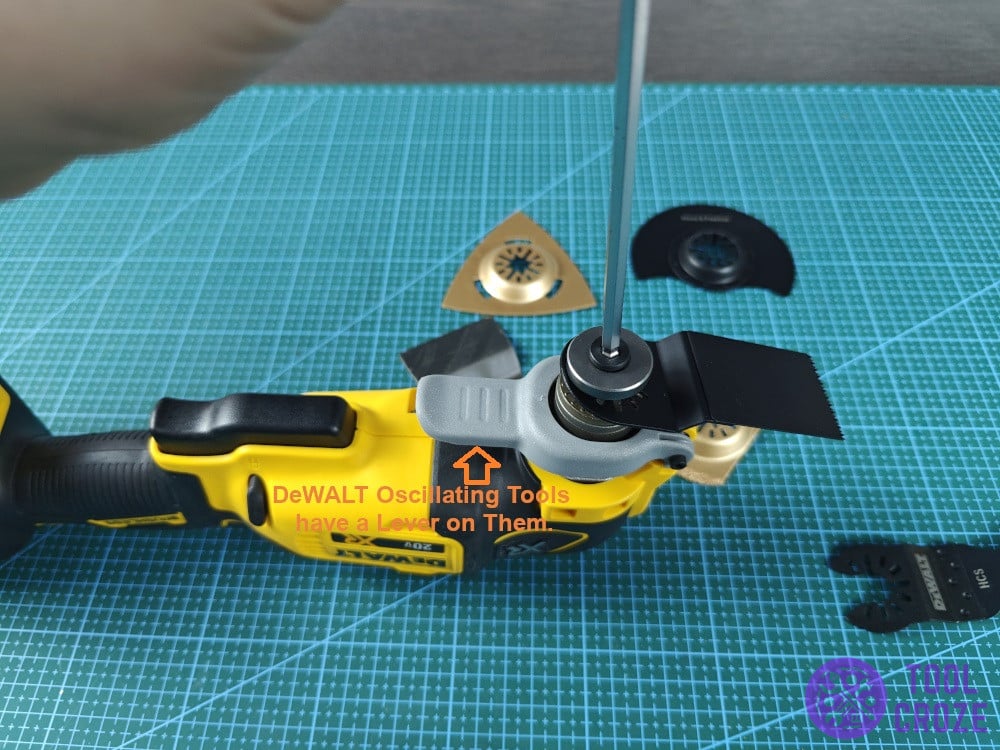

DeWALT oscillating tools have a lever on them. This lever is for holding and releasing attachments on the tool’s head. It makes switching between those attachments a lot easier as well.

Due to it holding the attachments down, it’s actually a super important component. Without it, the tool can’t work because nothing would be holding the blade down.

Looking around online, I saw that it’s really common for this lever to break off/stop working. It’s especially true with certain models, like the DeWALT DCS355. Without a lever, the tool isn’t usable.

Luckily, it’s not an impossible fix. It’s an easy one if you can find what you need. And what you need, is part number N254620. This is the name of the lever, and here’s a picture of it too.

It’s easy to find and buy online, and the best part is that it doesn’t cost much at all! It’ll only set you back by $8-$10, which is a lot less than what repairs would usually cost.

Once you have part number N254620, take the top screw out of the oscillating tool’s head. After taking it out, you’ll see a perfect place to fit the lever inside.

Fix the lever into the tool with the three lines you can see in the picture from earlier facing away from the oscillating tool. It’ll slot into place, and you’ll be able to attach blades!

- Tool Stops Working After Applying Force

A problem I’ve experienced myself is with force on the DeWALT oscillating tool. It cuts out as soon as users apply any force to it. Like pressing it against a hard surface.

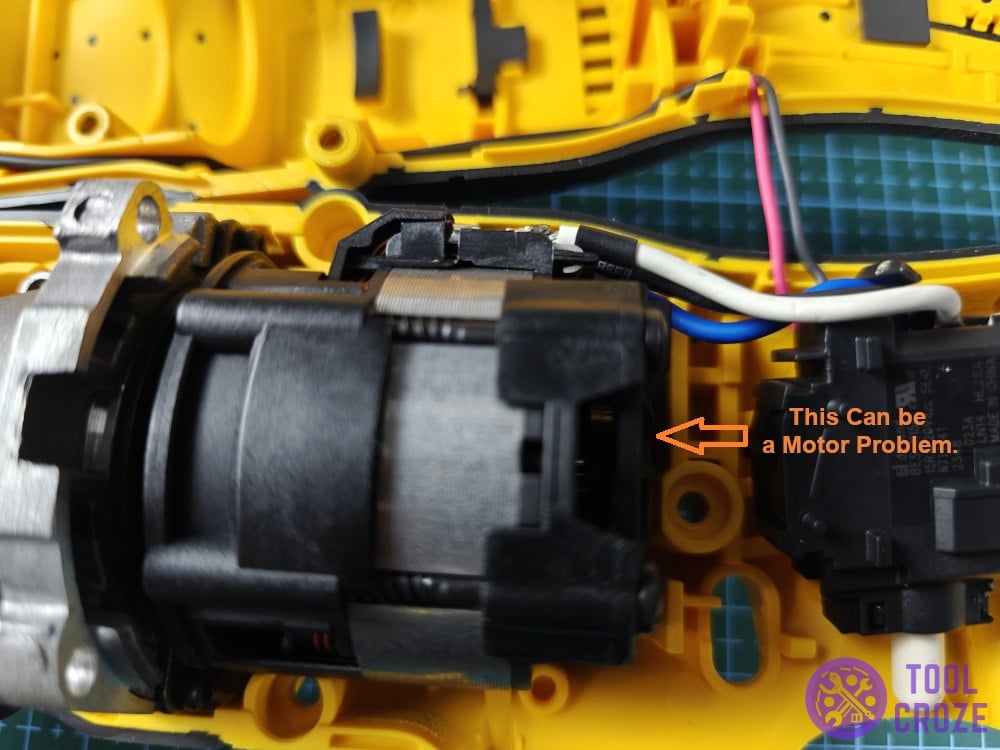

I wasn’t alone in this predicament either. A bunch of other people had the same thing going on with their DeWALT oscillating tools too. As I expected when it happened to me, it turned out to be a motor problem.

Once a motor can’t handle workloads, it’ll cut out. It’s a way for it to stop itself from burning out completely. That’s only supposed to happen when tools like this are exposed to super high workloads.

If the oscillating tool you’re using keeps dying out after the slightest force, its motor is dying. It can’t handle the tool’s purpose any longer, and you need to replace it to get things working again.

First, it’s important to confirm if the motor’s even dead, though. With some safety gear and a multimeter, power the tool with its covers open and check the voltage flowing from the motor.

If it’s really much lower than the manual specifies, you need a new motor. Getting one and fixing it will be a lot harder than the lever though, so I recommend inexperienced users don’t try this.

Getting it repaired directly by DeWALT or a mechanic might be a much better option. They’ll take care of finding the replacement and putting it back on without further issues.

- Misaligned Blade Issue

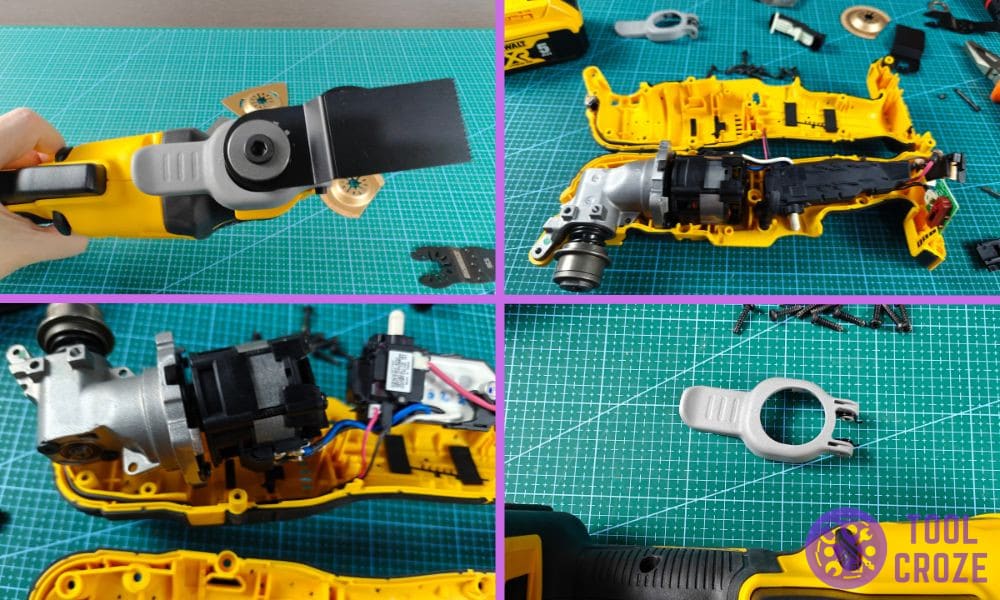

Something I saw a lot was people complaining about how their blade wasn’t sitting right on the DeWALT oscillating tool. The angle of it seemed crooked to them, and it’s just not lined up right.

This isn’t a problem with the tool, even though it might seem like one. Even though the blade seems out of place, it’s really easy to just move it around the way you want.

Just push the lever down and start moving the blade around with your hand. Adjust it to an angle you like, like I’ve adjusted mine in the image down here. It only takes seconds!

Lock down the lever in place so it stays that way even during use. Your blade won’t be out of order anymore, and you can use the tool without worrying.

Sometimes, the blade might get crooked between uses because of the forces that were acting on it the last time you used it. As you see though, it’s not that big of an issue.

Moving it back in place after pushing the lever is all you need to do. So, even though it might happen frequently depending on your use of the DeWALT oscillating tool, don’t worry about it too much!

However, in some instances you may really need to change the blade on your DeWALT oscillating tool. I have a short video which shows how you can do this and you can watch it below.

This is quite straight forward. If you are using the DeWALT style blade, you could just simply press the holder to release and install the new blade.

For the universal type of blade however, you can’t simply use the clip. Instead, you need the deWALT oscillating tool adapter to install the universal blade.

You would need a HEX key and install the blade as shown in the video.