Are you feeling that your DeWalt impact wrench is not strong enough to get the job done?

They’re pretty capable devices, and there’s likely something wrong that’s keeping them from getting the job done.

This can be one of the most common DeWalt Impact Wrench problems that I have discussed here.

Dewalt Impact Wrench Not Strong Enough

- Low Battery

The first thing I have to say is that you need to keep an eye out for the battery if you’re a wireless DeWalt impact wrench user like me.

It’s convenient how you can take them anywhere, but these devices still need power in their battery to function properly.

On a low battery, they won’t have much power to draw.

Similarly, on a empty battery, there is no power supplied to the impact wrench as well.

This will eventually mean that it can’t function strong enough to get the job done the way you want it done.

Sometimes you would even feel that DeWALT impact wrench is jammed and not spin as usual.

So, prevent your battery from getting low or empty.

Tips: Weak battery symptom like only can charge up to certain bars or cannot maintain its charge would also affect the tool’s performance

Use a multimeter to measure the voltage of your DeWALT battery to make sure it is healthy as shown in the video below.

You want all of these lights on the indicator below on whenever possible.

If your battery is not charging at all, view this video below to to see how I fixed this issue.

- Loosen or Worn Out Anvil

The anvil is one of the most important parts of your impact wrench.

It’s responsible for managing the force of impact and bear the load.

But, if it loosens or gets worn out, you’ll notice a decrease in performance like the impact wrench is not impacting as it should be.

A bad anvil can cause socket slippage, and it’s not capable of managing the energy from your impact wrench’s rotations.

Besides, you might also notice it is difficult to attach and detach the socket from the impact wrench anvil if it no longer in perfect shape.

I have recorded a video to demo how to change the anvil on impact wrench.

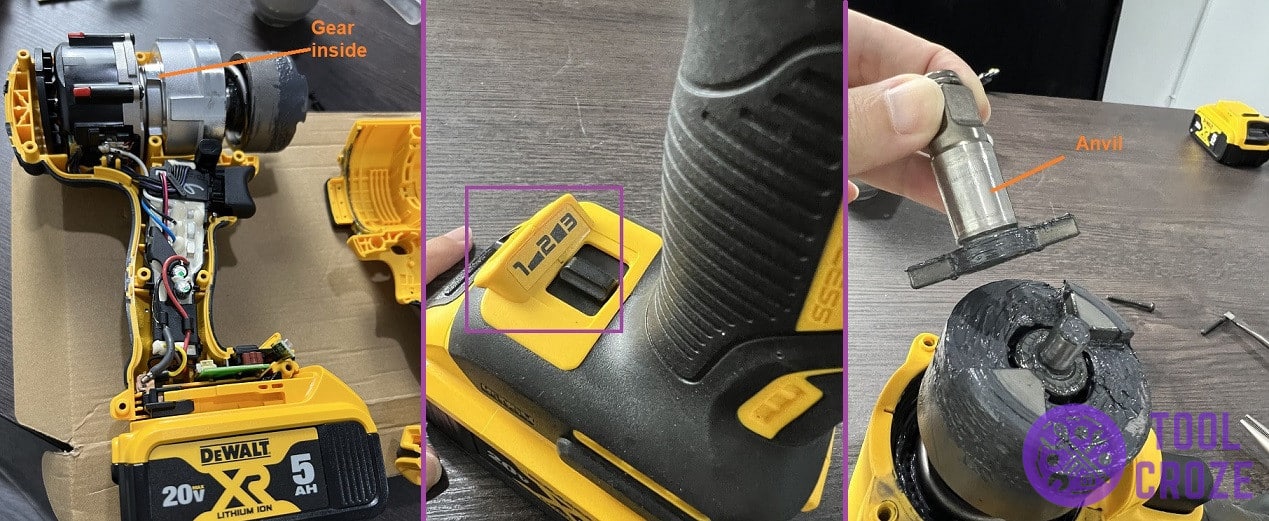

Here’s what the anvil looks like. If yours doesn’t look like mine does, and instead looks damaged, rusty, or worn out, get a replacement for it.

Also, make sure there is no grease leaking issue on the impact wrench.

- Socket Size Is Incorrect

The socket on your impact wrench needs to be the right size for obvious reasons. It should fit perfectly with the anvil, otherwise problems like this pop up.

A socket that’s too big or small causes incomplete engagement.

That results in an unstable grip while you’re working with it and can cause slipping.

This is both ineffective and dangerous. I can’t stress enough how you shouldn’t use the device in this state.

Plus, the socket might get damaged if it isn’t the right size.

Even worse, it could damage other components. I should also mention that the wrong socket size results in less torque being transferred, which leads to less strength in the device’s function.

This is why you could be feeling that it’s weak.

- Incorrect Torque and Speed Setting

Your DeWalt impact wrench has torque and speed settings that effect its functioning.

This is what the settings look like on my DeWalt Impact Wrench, from setting 1 to setting 3.

If you feel like your device is too weak, consider using these to your advantage.

If 1 feels too weak, try switching it to 2.

If that’s not enough, 3 is sure to get the job done.

Read this post to troubleshoot impact wrench torque/speed settings related issue.

- Motor Issues

Your motor should always be in top condition. It’s the powerhouse of the whole device, and should be taken care of.

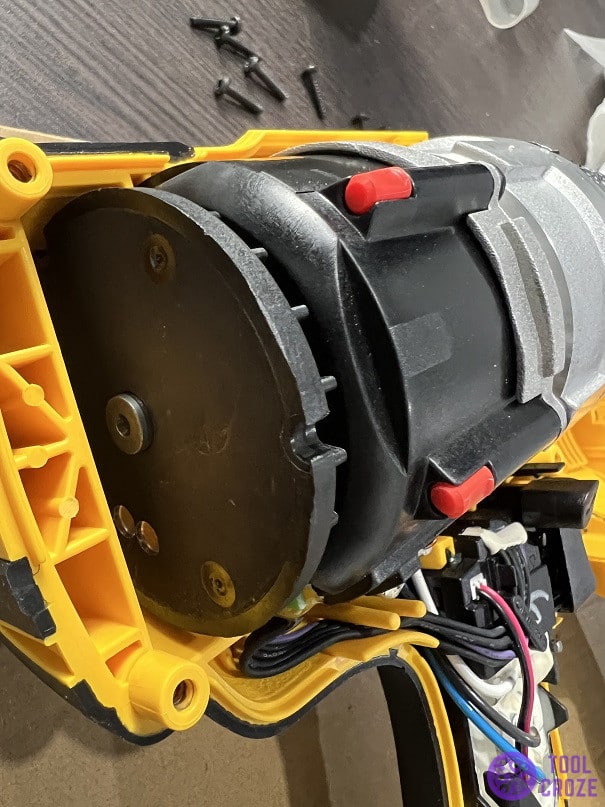

That said, take the cover off your impact wrench like I did here, and take a good look at the motor inside.

Confirm if there are any cracks or damage on it or around it.

- Inspect the motor housing for cracks or damage

- Any abnormal vibrations

- Keep the motor vents clear of debris

Plus, I want you to pay attention to the device itself when you turn it on and use it.

Are there any strange or extra strong vibrations?

If your answer is yes, that likely means there’s something wrong with the motor.

I recommend giving it a good cleaning, and making sure you regularly check it for debris getting inside or around it.

- Overheat

The DeWalt impact wrench is a heavy duty device, but its not unbreakable.

You need to take good care of it, or else it won’t be able to do the things you need it to do.

Give it time to cool off when you’re using it a lot, as it can easily overheat with extensive work.

It has duty limits, and you should pay close attention to those while using it so that it doesn’t burn out.

- Internal Gear Issues

I’ve got another thing that needs you to take off the cover.

This time, you have to check the gears inside the device. To give you an idea, I took my covers off to show you what you’re looking for.

Inspect these gears thoroughly and make sure there’s no sign of damage or debris.

Keep these clean and secure, as they’re very important for the strength of your impact wrench.

A thorough cleaning of the drill every week is also a good way to manage this and avoid possible Impact Wrench not turning issue.

- Use It On Suitable Task, Not Overloading

If none of the things I’ve said so far have worked out for you, I think it might be time to consider that your DeWalt impach wrench actually is not strong enough for the task at hand.

Like all devices, they have a limit, and you could potentially be making yours work past its limit.

I know that there are some arguments talking about whether you should use impact wrench to remove lug nuts or not.

For my own case, I use my DeWalt impact wrench to remove the lug nuts on my car tires as shown in the image below and it worked great!

Read: What To Do If Impact Wrench Cannot Remove Lug Nuts

Only use the tool for what it can do, as otherwise you’re just asking for it to break.

Tips: I actually converted my DeWalt Impact Wrench To Impact Driver as it can work

Conclusion

I’ve been in situations where it felt like my DeWalt impact wrench is not strong enough for my needs.

But, all the tips I shared with you above are things that helped me in situations like that.