Impact drivers are some of the most common power tools out there. Since they usually have more torque than drills, they’re great for larger, tougher screws into hard surfaces.

Without impacting, though, it can’t do all that. So, if you’ve got a DeWALT impact driver that’s not impacting, start with the tips below to find a solution for this.

Read: How I Solved My DeWALT Impact Driver Trigger Problems: Tips

3 Tips To Deal With A DeWALT Impact Driver That’s Not Impacting

- Know The Tool’s Limit

I know they’re called “power tools”, but impact drivers aren’t THAT powerful. There’s a limit to what they can do, just like any other tool. You can’t do every job in the world with them.

What I’m trying to get at, is that are you just trying to do something that your DeWALT impact driver can’t handle? A job that’s too much for the tool to do because it isn’t strong enough?

Because if you are, that may be why it seems like it’s not impacting. It literally can’t impact whatever you’re trying to use it for, hence why the tool seems like it isn’t working right.

This includes jobs that require more torque or power than the tool can provide. It can’t impact properly in situations like that, which will lead users to believe it’s not impacting at all.

Researching is the only real way to figure this out. For starters, know the specs of your impact driver. How much torque does it have? What kind of jobs is it good for? Stuff like that.

Then, you’ll have a better idea of things it can’t do. For example, it might not be impacting cause the screw you’re trying to use it for is way bigger and sturdier than what the tool can deal with.

Avoid doing things like that, because they’re a recipe for burning out the motor inside a DeWALT impact driver. A burnt-out motor will stop the tool from impacting ever again.

There’s no safe workaround to using a tool for something it can’t handle. So, use this as a tip to avoid damaging your tool beyond repair. Don’t force it to start impacting.

I have made a short demo video about the different tasks which you can use your DeWALT DCF787 Impact Driver. You can watch it below.

You can use your DeWALT impact driver to drive short and long screw or a long bolt into a wood. You can also use it to step drill bit to drill through an iron plate.

I’ve also shown in this video how to use your DeWALT impact driver in drilling through concrete with a small bit and through concrete with a big bit.

- Weak Battery

Tough jobs are one thing, but is your DeWALT impact driver not impacting even in situations where it would normally work? That may be because of the battery.

The battery is responsible for powering the motor, which is responsible for powering the “impact” function of these tools. Without a proper battery to power the impact driver, it won’t work right.

By a weak battery, I’m not talking about one that has low charging. No, I’m referring to a battery that’s dying and losing its capacity. DeWALT batteries do go bad after some years, after all.

Testing out a new one will answer if the battery is really what’s stopping the tool from impacting. That’s why I suggest doing that next. Just to write this possibility off, if nothing else.

One of two things can happen. It’ll either work, and you know that the battery you were using before is what was stopping the tool from impacting.

When that happens, the solution is to stop using the old battery. Get a new one or switch to a spare if you have it available. That’ll get the tool impacting reliably again.

Or… it won’t work, and you know that this isn’t because of the battery. When that happens, do as I’ll say in the last tip below.

Before you buy a new DeWALT 20V battery, you can try to reset it first. I have a video which shows how you can do this and you can watch it below.

You need another healthy DeWALT 20v battery in order to do this. Connect B+ to B+ terminal and B- to B- terminal of the two batteries.

Let them stay connected for around 15 seconds and then try to jump start the problematic DeWALT battery.

- Weak Motor

If it’s not a weak battery, there are only two possibilities. One is that the impact driver is heavily damaged and no longer works right due to broken mechanisms. That’s obvious to notice, though.

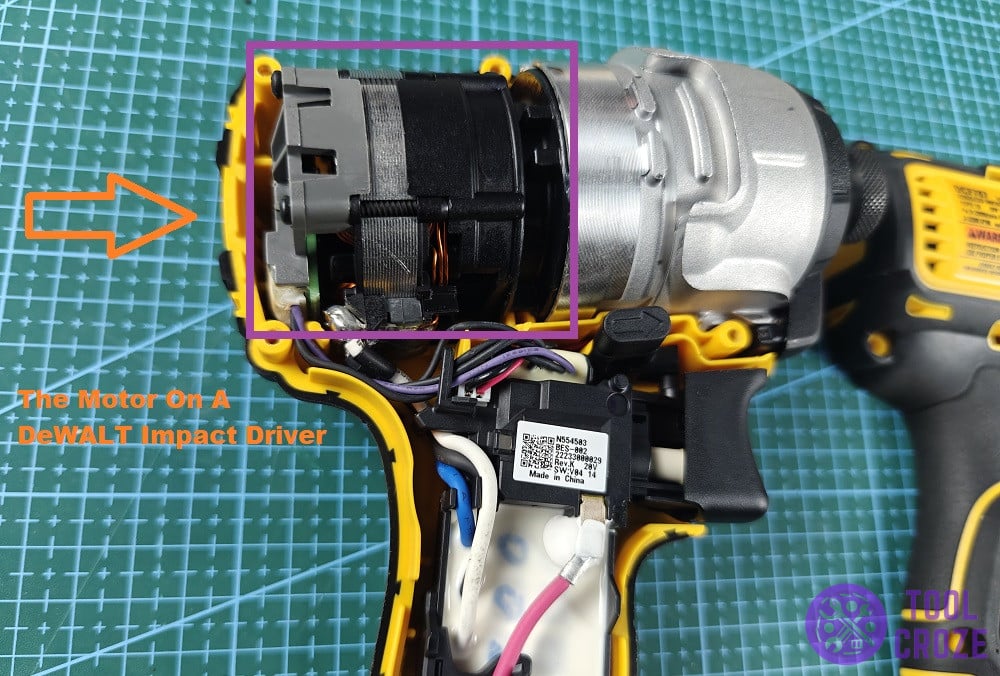

The other, and likelier situation, is that the motor isn’t working right. It’s too weak now, likely due to age or overuse. It’s no longer providing enough torque for the tool to work right.

You need a replacement motor. If you don’t want to handle repairs, buying an entirely new DeWALT impact driver is an option too. It’ll be a better investment for the future.

But, if you want to fix the tool you currently have, a new motor is what you need to get it working again. Start by getting a suitable replacement by searching online.

With the covers off like in the picture above, you’ll have a better view of the motor. With that, start by removing all the wires from the motor one-by-one. Nothing should stay attached.

Then, start repeating your steps in reverse with the new motor. Place the new motor where the old one was, and start connecting the wires as they were onto it.

With the wires on, get the covers and screws back on the tool. After everything is in place and the tool is ready to use, give it a whirl. It should be impacting perfectly!