Good power tools don’t come cheap. The Milwaukee M12 SDS rotary hammer drill’s price tag is an example of that. More often than not though, it’s a good investment for those that plan to use it regularly.

However, some unlucky few may not think that right now. You might be one of them if your Milwaukee M12 SDS rotary hammer drill is not spinning and hammering, but I’ll help you troubleshoot this problem!

Milwaukee 12 SDS Rotary Hammer Drill Not Spinning and Hammering – 4 Fixes

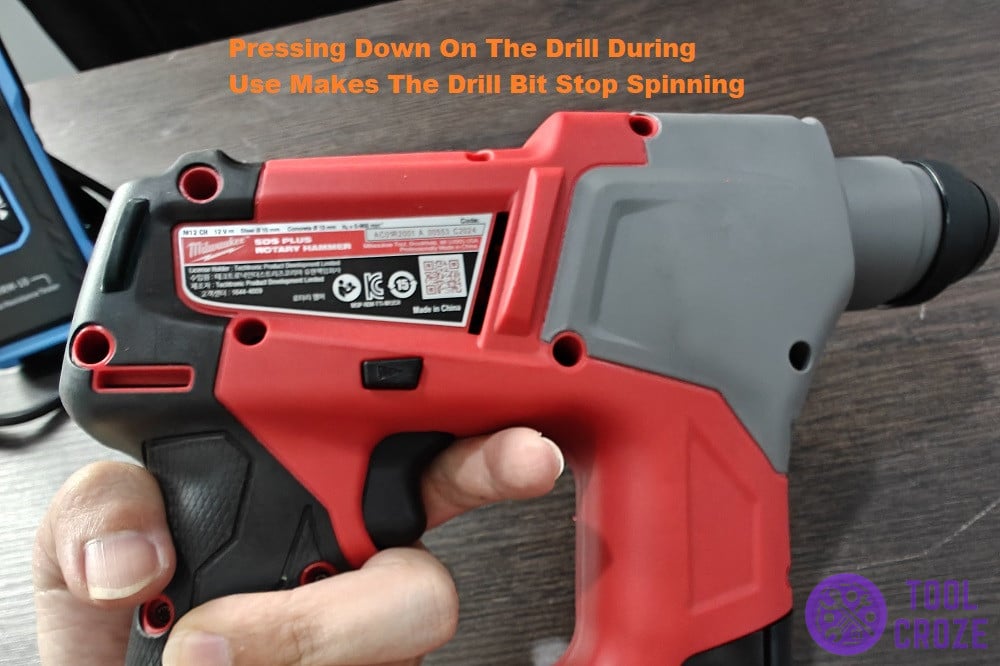

- Don’t Press Down Too Hard

Surprisingly, power tools don’t do too well when you force them along. That sounds wrong, no? You would think that a power tool would be pretty good at withstanding force.

Well, it is. At the same time, however, they also aren’t. Power tools like the Milwaukee M12 SDS rotary hammer drill can easily handle heavy workloads.

The important thing with that though, is that users are supposed to let them handle those loads on their own. What I’m trying to get across is that you should never press down too hard when using these tools.

Instinctively, or maybe due to muscle memory because of how non-battery-operated tools work, new users might push down on rotary hammer drills when using them.

In truth, doing that does more harm than good. The extra pressure is unnecessary and only adds to the force acting on the tool. It further restricts the movement of the SDS drill bit.

Just don’t put any weight on the tool when using it. Let it do its thing while simply holding it in place. That will get it spinning and hammering again just fine!

I have made a demo video which shows the correct way of using your Milwaukee M12 Rotary Hammer SDS drill to drill on a concrete surface. You can watch it below.

As you can see, I didn’t exert much force in pushing the drill down the concrete.

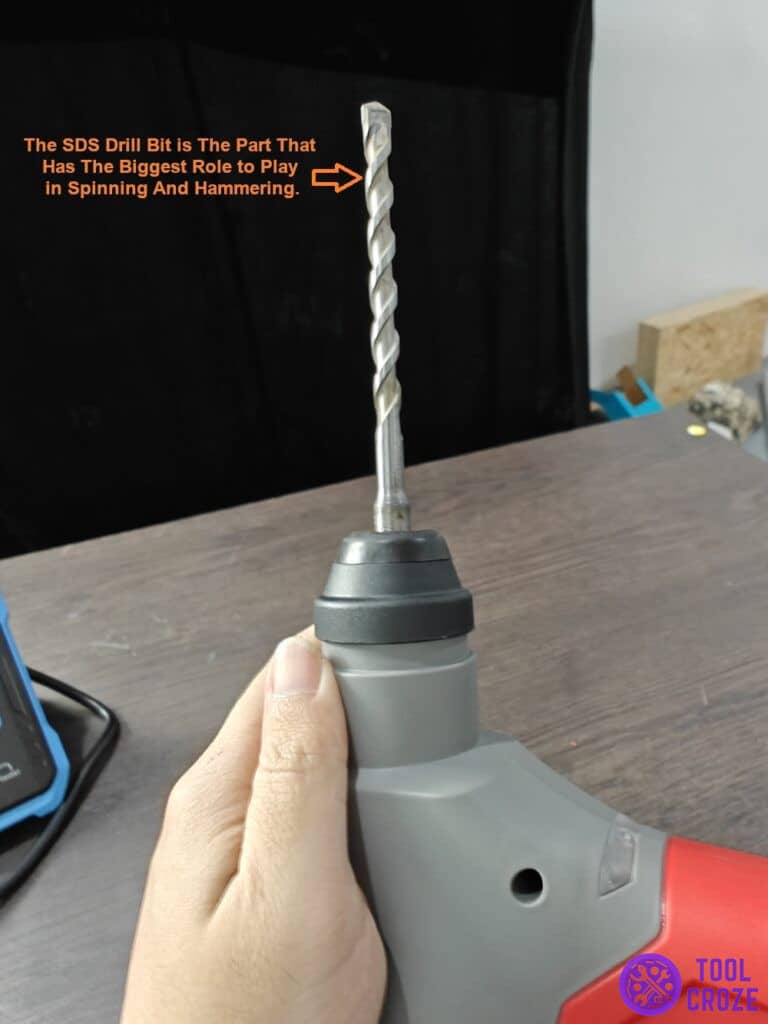

- SDS Drill Bit Is Loose

The SDS drill bit is the part that has the biggest role to play in spinning and hammering. After all, without one of those, the drill chuck would just be spinning around aimlessly.

That’s why it’s also the component that has the biggest role to play in issues with spinning and hammering. So, that’s the part I recommend checking next, starting with its positioning.

A loose SDS drill bit is enough to cause this problem. Not being properly set in the drill chuck stops the bit from spinning around, which also means it can’t hammer through surfaces.

Take it out like I’ve done in the image below, and secure it back afterward. Lock it in place tight, but not so tight that it might stop the SDS drill bit from spinning around.

One more tip I have before moving on is to clean out the drill chuck after taking the SDS drill bit out. Sometimes debris is what stops things from spinning and hammering.

It’s just another restriction that gets in the way of the tool’s movement and functionality, so get it out of the way! Use cotton swabs to scoop out dirt and debris in order to rule this out.

- Are You Using Good SDS Drill Bits?

Never settle for anything but top quality when it comes to SDS drill bits. Power tools need to be in top condition to get hard jobs done. Without a good SDS drill bit, that isn’t possible.

I’ve already made their importance clear. With that in mind, it’s clear why using bad-quality SDS drill bits can stop the spinning and hammering of the tool.

I always use the bits that come with my tools, which you can see in the picture above too. When I have to purchase them separately, I try my best to get the parts that suit my tool the most.

Sure, it might cost a bit more to get the best SDS drill bits for your Milwaukee M12 SDS rotary hammer drill. I can guarantee it’s worth it compared to buying flimsy ones though.

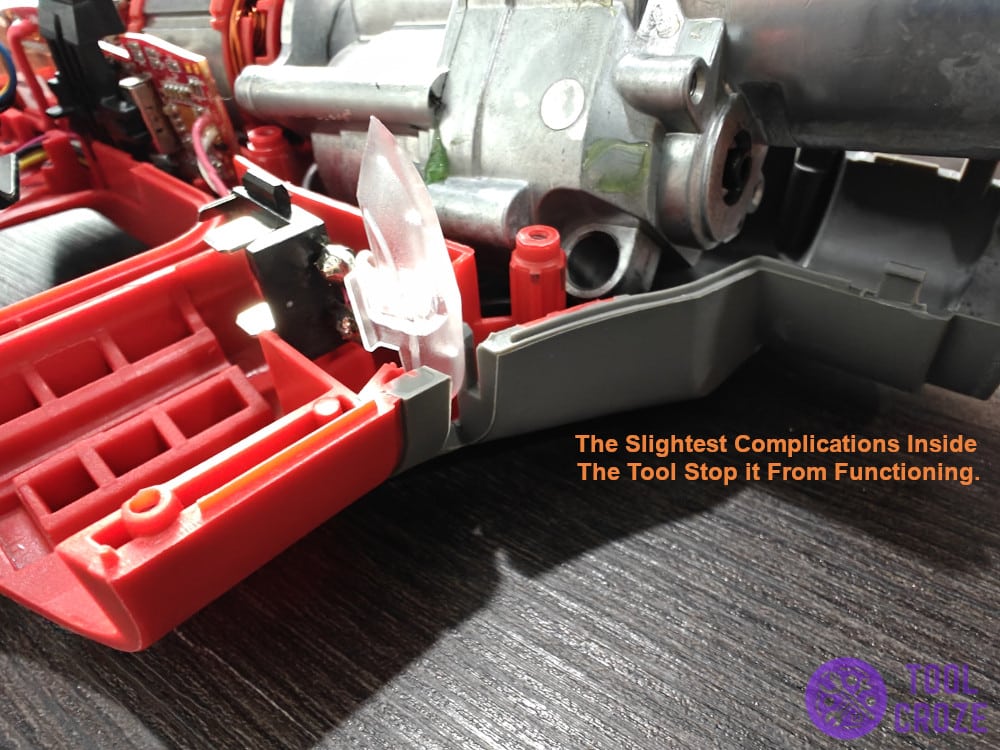

- Faults Inside Are Stopping Movement

When the SDS drill bits and drill chuck are both clear of any blame, it’s usually internal components that hold the blame. The slightest complications inside the tool stop it from functioning.

There’s no more torque, so the Milwaukee M12 SDS rotary hammer drill isn’t spinning or hammering like it should. The answer for dealing with that depends on your particular tool.

It isn’t a specific thing that may be causing this. A burnt-out circuit board, faulty wires, etc. can all be responsible for this. The best way to find out is by directly inspecting the way I’m doing below.

In case you find anything wrong, repairs are the next step. Damage to boards, chips, and wires isn’t easy to deal with at home. It’s a lot better to let professionals repair those things for you.

Check for debris that may have entered the tool. Good hotspots for that are behind the trigger, around the motor, drill chuck, and other sensitive components like that.

Whether you choose to do it at home or have someone else do it, dealing with those internal issues will get the Milwaukee M12 SDS rotary hammer drill spinning and hammering again!