Rotary cutters are great for making small cuts. A lot of patchworkers and tailors use them for working with fabrics. But, these tools can’t cut through anything if they have issues.

I’m guessing that you’re facing said issues if you’re reading this. Well, I have a troubleshooting guide ready here to tell you all about common electric rotary cutter problems and solving them!

4 Common Electric Rotary Cutter Problems (Troubleshooting)

- Not Cutting Through Fabric

The main reason why a lot of people use these tools is for working with fabric. So, it’s pretty problematic when their electric rotary cutter isn’t cutting through fabric. It’s pretty common among new users especially too.

For a lot of people, it’s just an issue with the way they’re using the electric rotary cutter. For example, they might not be using the right technique, which is common when you aren’t too familiar with the tool.

There are a lot of things to take into account, and mistakes are common at the start. Use some extra fabric to practice, and that will help you develop the perfect technique for you.

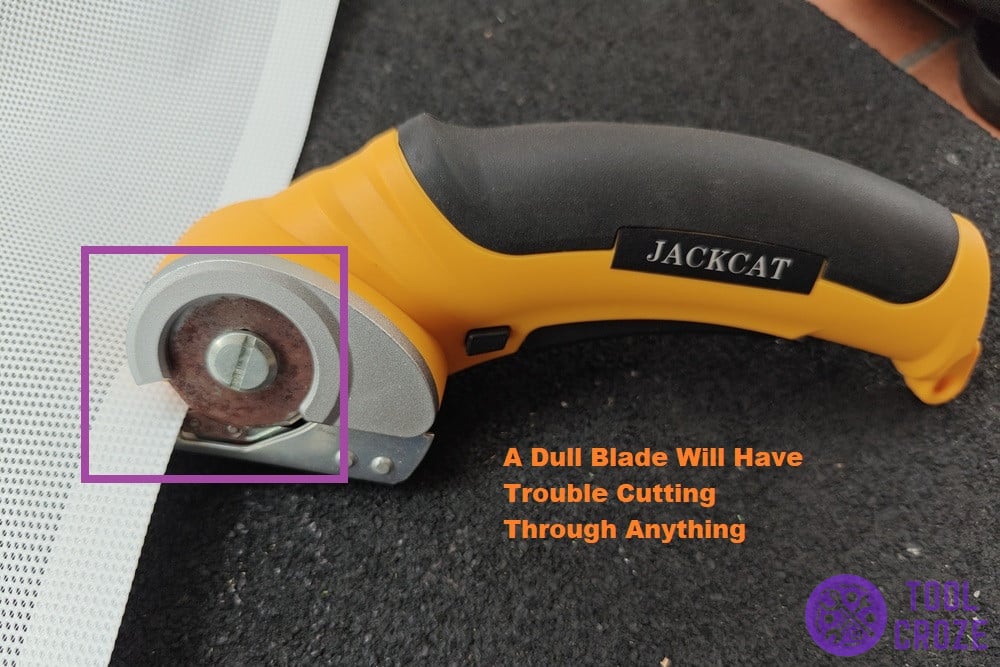

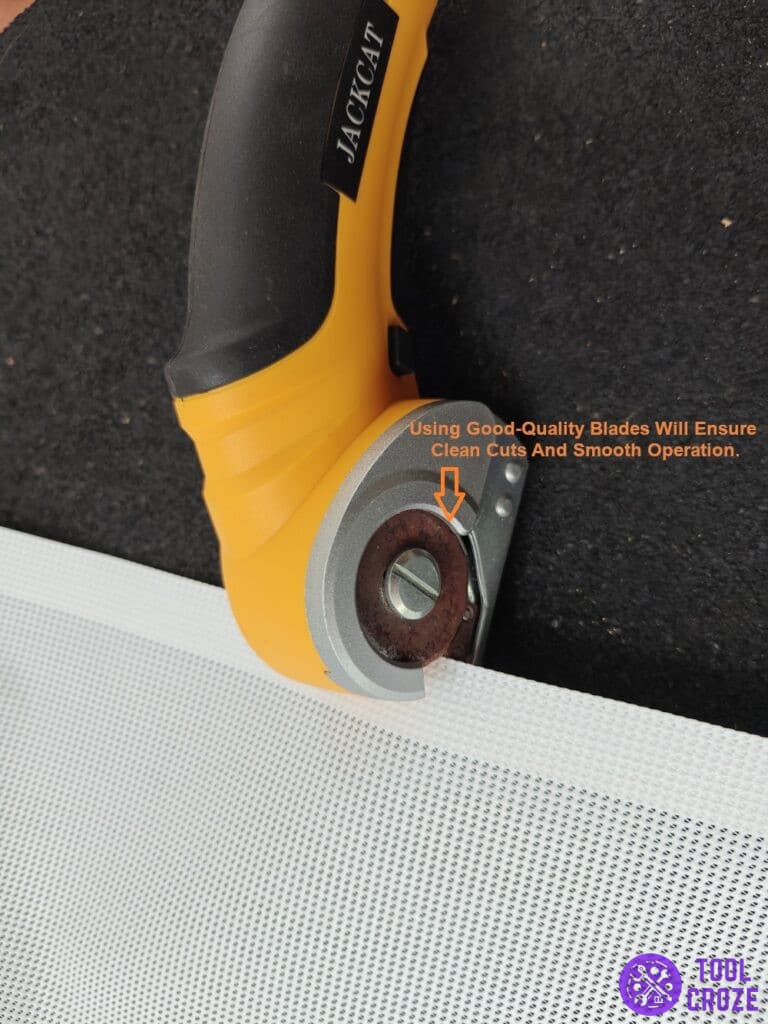

One other thing I want to mention is the quality of the blade itself. Don’t use cheap or dull ones. You can see me using one in the picture above. Notice how the fabric isn’t cut at all because of that.

Always use good-quality blades. It will ensure clean cuts and smooth operation. Dull blades with rough edges might ruin the thing you’re cutting, and cause problems during use.

- Loose/Tight Screws

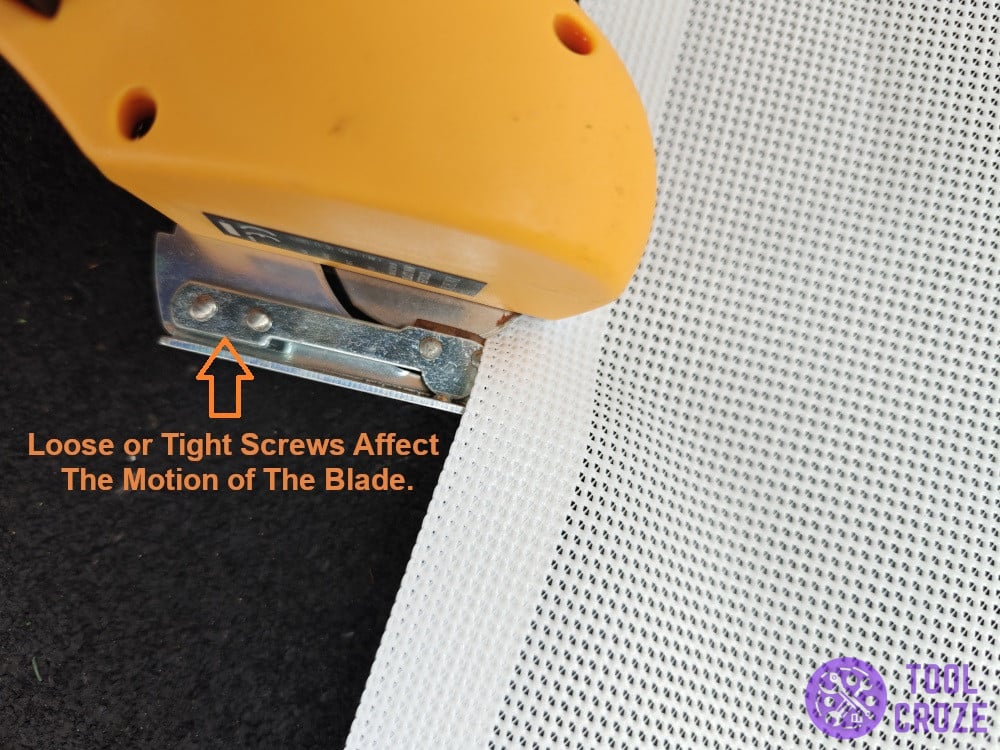

Too much of anything is bad. I’m sure you know about that saying. Well, it applies to electric rotary cutters too. That’s because screws that are too loose or tight are both terrible for the bladed.

Loose screws or overtightening will cause problems with motion. Screws being too loose will give the blade too much room to move around in, which will stop it from reaching optimal speeds.

On the other hand, screws that are too tight will slow the blade down or stop it entirely. So, take a good look at the screws and ensure that there aren’t any issues.

One more thing I wanna mention before we move on is that the screws get looser on their own sometimes. This is normal and happens to my electric rotary cutter too.

You might need to regularly tighten the ones on your tool to make sure they stay proper.

- Improper Assembly

You’ll need to disassemble the electric rotary cutter’s head when you want to put a new blade inside. The screws I was talking about in the last solution are a part of this process.

Once you add a new blade, you then have to reassemble everything again. This is where things can go wrong since some people make mistakes during assembly.

Anyone who doesn’t have much experience with electric rotary cutters is prone to this. They have small parts, and assembling anything incorrectly or in the wrong order is easy.

Don’t worry about it too much though. At most, the wrong assembly will prevent the tool from working. You can easily resolve this by reassembling it the proper way so nothing’s wrong.

Take off all the parts use your device’s manual or an online guide for your specific model and assemble it properly this time. Do it in the correct order too, so that there’s no complication during use.

- Not Turning On

For many people, the issue often has something to do with the blade. But, for some, it’s an entirely different case; the tool just won’t turn on.

While this is less common than the other things I talked about today, it’s still common enough that I want to discuss it. So, what exactly prevents an electric rotary cutter from turning on?

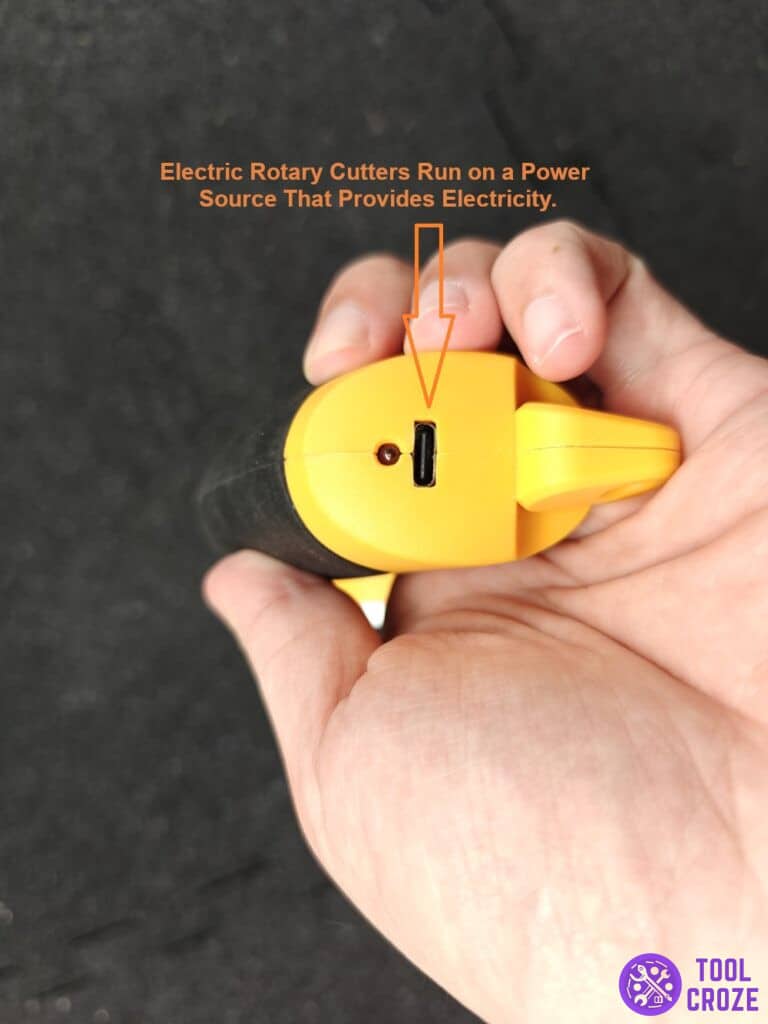

Well, these are “electric” rotary cutters. So, that means they run on a power source that provides electricity. If something happens to that power source, it won’t be able to turn on.

That is probably what’s going on with your tool too. But, before blaming the battery, inspect the charger first.

I took a picture of my charger, which you can see above. My rotary cutter uses a simple USB port for charging. While my charger is fine for now, yours might not be.

Try a different charger of the same type, and see if it is working for the tool. If even that doesn’t work, then it’s time to start pointing fingers at the battery.

Unfortunately, unlike battery packs for other tools, there’s not a lot to do about the batteries for these tools.

Instead of repairing them or replacing the batteries in them, it’s usually best to just get an entirely new rotary cutter. They aren’t expensive tools, and an entirely new tool will last you much longer.