Any tool can start acting up after a bit of time. Heck, some of them do it straight out of the box. But, that’s not something to worry about too much, especially if your tool is relatively new.

Same advice goes for the DeWALT grinder, which I want to help with troubleshooting today by talking about its most common problems. Most of the regular issues with the tool are in this list, so just look it over:

Common DeWALT Grinder Problems and Their Troubleshooting

- Grinder Blade Wobbles

I think the most common complaint anyone’s going to find about this tool is how much its blade wobbles. That’s obviously alarming, since it’s a part of the tool that needs to be sturdy and stable.

But, despite it looking like a bad thing, it’s usually not. The grinder blade wobbling is a normal thing that’ll happen every now and then. That’s why it’s such a common complaint.

It’s one of those things that comes naturally with the use of this tool; especially if you work on harder surfaces. During heavy-duty work, the screws holding the bit get loose and you have to tighten them again.

Always use a wrench and proper tools to tighten the grinder bit. Bolt it down tight and you have nothing to worry about. And, whenever it gets loose again, just keep doing the same thing!

I prefer securing the grinder blade after every other use– just to be on the safe side. It’s not something that takes a lot of time and prevents a wobbling, so why not, right?

However, if even tightening isn’t doing the trick, it may be that your bit is aging. A grinder bit that starts wearing down will also start to lose its shape a little. Because of that, it wobbles even when in place.

It’s no longer functional to the fullest and starting to show its age. That’s when users know it’s time to replace it and get a new one that’ll stay in place just fine.

- Weird Noises During Use

Are you hearing something weird when trying to use the DeWALT grinder? Like any kind of rattling or shaking, or whatever? If you do, I suggest turning the tool off ASAP.

Stop using it, as there’s a loose component inside going all over the place. Now, it may be something small, like a screw. But, it could also be something big, like a plastic piece that came off a component.

Regardless of what it is, it’s dangerous for the tool. Loose components like that can come into contact with other parts of the tool and damage them, which is why it’s best to stop using it for now.

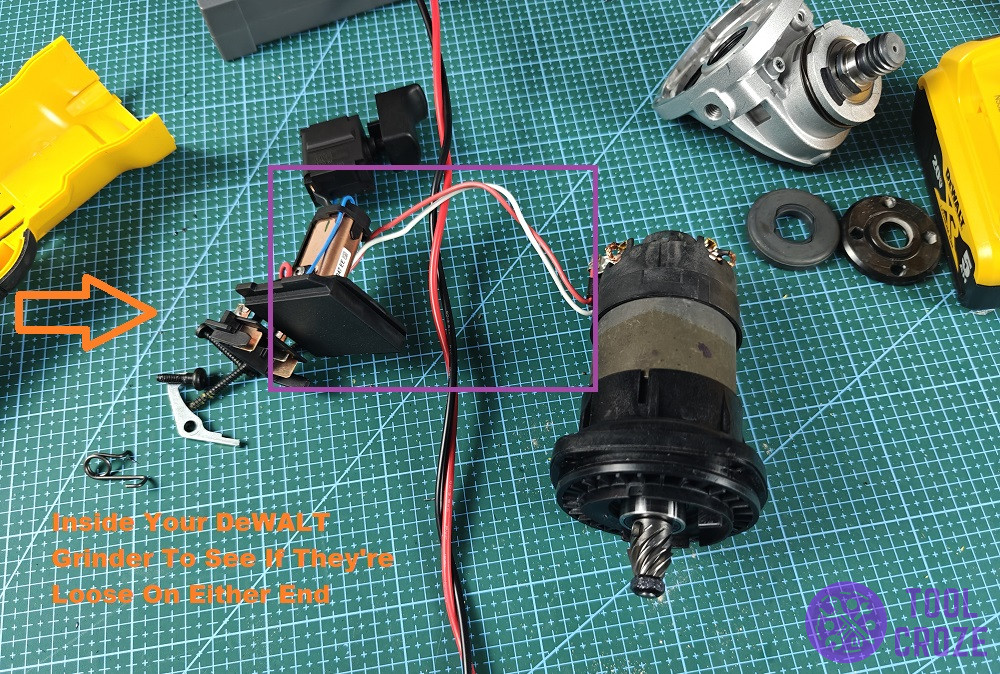

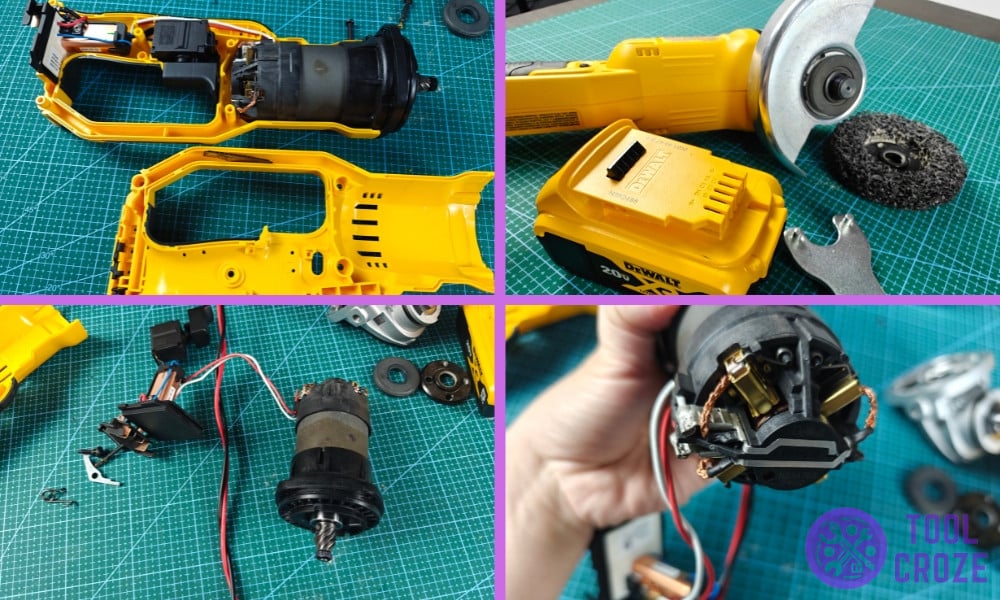

Instead, do like I did in the photo down here and open up the casing to see what’s inside. There isn’t a whole lot in there, so anything rattling around should be pretty easy to spot.

Loose components should usually just fall right out after you open the covers and move the tool around a little. But, even if it doesn’t, finding it shouldn’t be that hard.

After you see what’s wrong, put the loose component back in its place. If you’re unsure about where it should go, the manual will make the job a lot easier for you since it’ll say part numbers and where they go.

- Disconnected Wires Around Motor

There’s a specific set of wires inside the DeWALT grinder that tend to go loose for some users. Once they do, the whole tool stops working. No inputs register, and the tool just doesn’t work.

It’s a pretty common thing, that needlessly costs people a lot of money to fix. That’s just because users don’t know about what’s going on, though! It’s actually super easy to fix.

Motors on the DeWALT grinder have a set of wires attached to them. Sometimes, these wires may disconnect. This is why the tool stops working, as the motor no longer has any power.

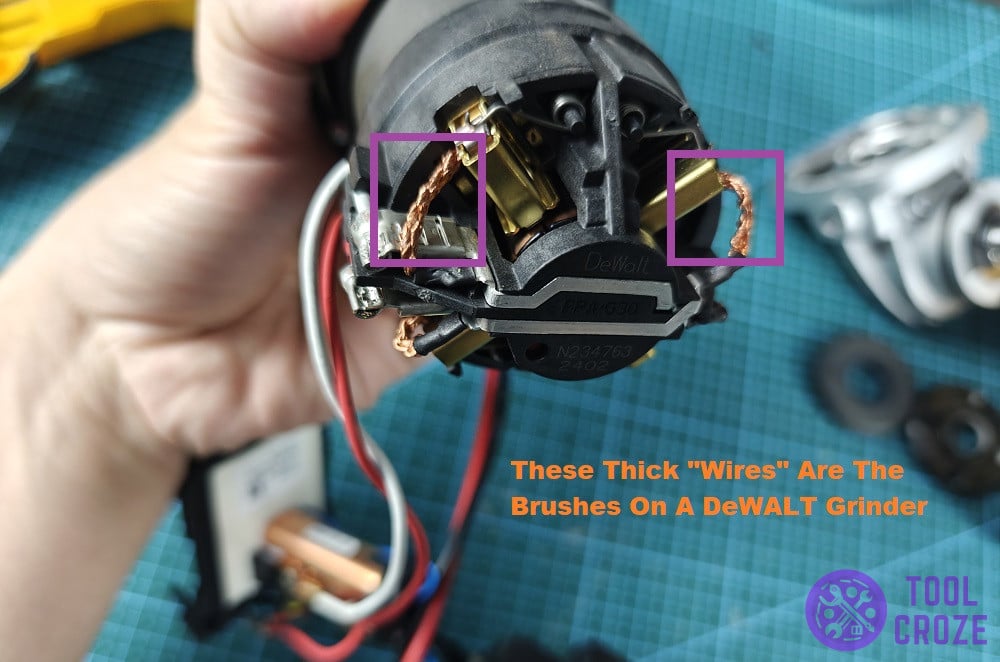

Here’s the set of wires that I’m talking about (see picture below). You have to open the covers for this fix too, in order to get a good look at the motor and see if its wires are loose like I said.

In case any aren’t connected right, you’ll have to solder them back into place. Soldering isn’t an easy job, though. If you have no prior experience with it, I don’t suggest taking it on yourself.

Get someone that knows more about it to take care of the wires for you. Since you know more about the exact problem, getting repairs won’t be nearly as expensive either as it’s a simple soldering job.

- Bad Brushes Inside Grinder

My DeWALT grinder is a brushed model. A very common problem with any brushed tool, is its brushes eventually going bad. This is common because it’s unavoidable.

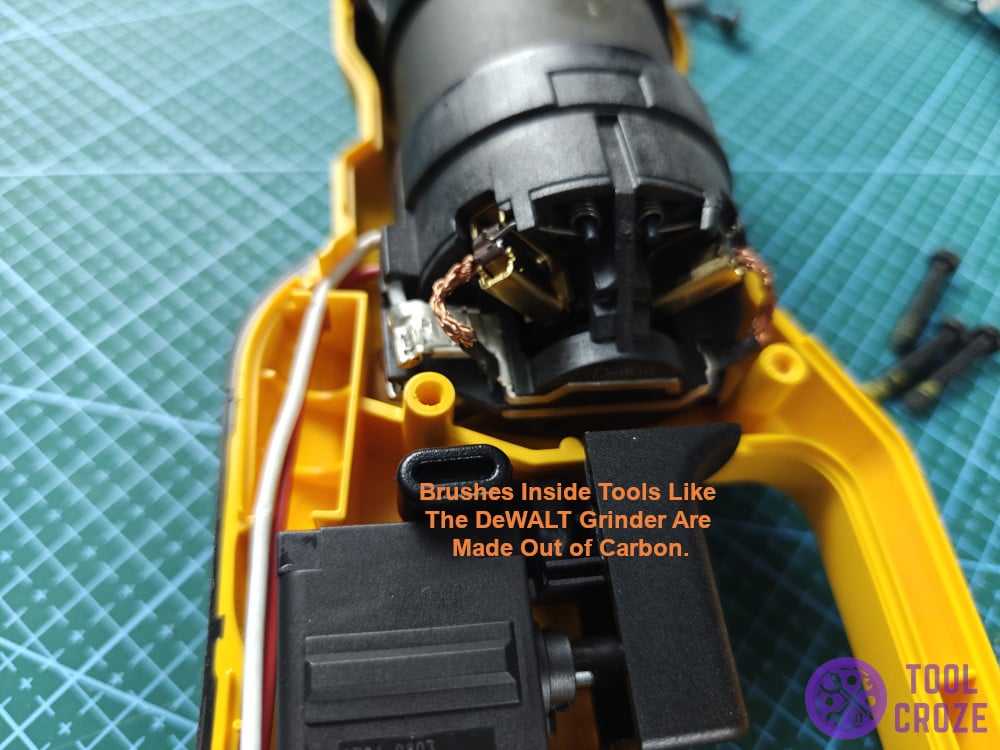

Brushes inside tools like the DeWALT grinder are made out of carbon. All the friction that carbon is subjected to regularly eventually wears it down, which is why brushes go bad.

They start getting smaller in size due to that. It happens gradually, and comes to a point where they either have too much damage for stable use, or are too short to work with the tool any longer.

This stops the tool from working, since the brushes play a big role in the motor’s function. Take a close look at the brushes on the tool, as I’m doing in the image down here, to see if that’s happening.

Bad brushes don’t have any fixes, really. They’re just no longer in any condition to keep helping the DeWALT grinder function. So, the only step to take is replacing these brushes.

While replacing them is easy, the hard part is finding a suitable replacement. While on the search for new brushes, ensure that you get the perfect fit for your specific grinder.

Look for brushes that will fit your tool’s model number, and are specifically made for it. Using incompatible brushes will render the grinder useless until compatible ones are added instead.