Ran into some trouble with your DeWALT blower? A quick look online will show you aren’t the first one, at all. It’s a tool that’s basically infamous at this point for being problematic.

There’s no doubt that it acts up, but it’s also useful when it works. So, let’s get it working again. Follow these tips on common DeWALT blower problems and their troubleshooting to know what to do!

Troubleshooting 4 Common DeWALT Blower Problems

- Defective Models

Now, I already talked about these tools being kind of infamous. Well, that’s because a lot of them just don’t work right. It’s a really annoying issue, especially one that plagues older models.

By this, I’m not talking about some kind of small issue. No, I mean that they literally just don’t work as they should. They’ll be straight out of the box and still won’t function as they should.

Instead, what happens is that the blower turns on for a few seconds, and then immediately turns off on its own again. This happens each time users turn on the tool.

It doesn’t matter if they change batteries, or try whatever fixes. The truth is that the models that do this are just defective most of the time, especially if they’re doing this straight out of the box.

Does that sound similar to whatever’s going on with your DeWALT blower? Well, if so, I suggest you don’t try any troubleshooting at all. If your blower is new and doing this, it’s defective.

What you should do instead is contact the company as soon as you can. DeWALT offers warranties for this exact purpose, and you can easily claim refunds or get your current blower exchanged for a new one.

I don’t want you to try troubleshooting is because tampering with the tool can void it’s warranty. This is a very widely known problem with DeWALT blowers with no fix, so get a refund instead.

- Won’t Stay On

I know this sounds like what I just talked about. But, I also want to talk about it for people that don’t have defective models. Sometimes, the DeWALT blower still won’t stay on even if it was working fine before.

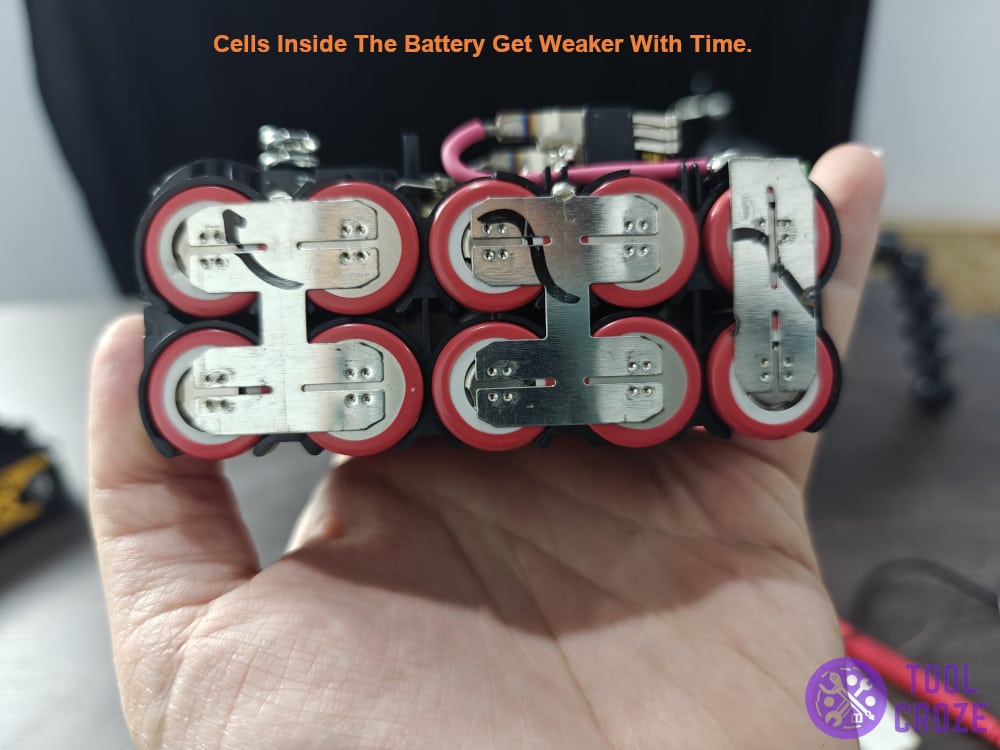

The battery could be getting weaker, leading to reduced output that can’t power the tool reliably. Cells inside the battery get weaker with time, and people eventually need to replace them as a result.

I have made a short video which shows how you can identify a bad DeWALT battery cell and you can watch it below.

In this video, I opened the cover of my DeWALT battery and set my multimeter to measure DC voltage. I use the red probe to touch the battery side with red wire and the black probe to touch the battery side with black wire.

Each battery cell should have an output voltage between 3.6V to 4V. If the measured voltage is less than 3.6V or more than 4V, it means that particular battery cell is not good anymore.

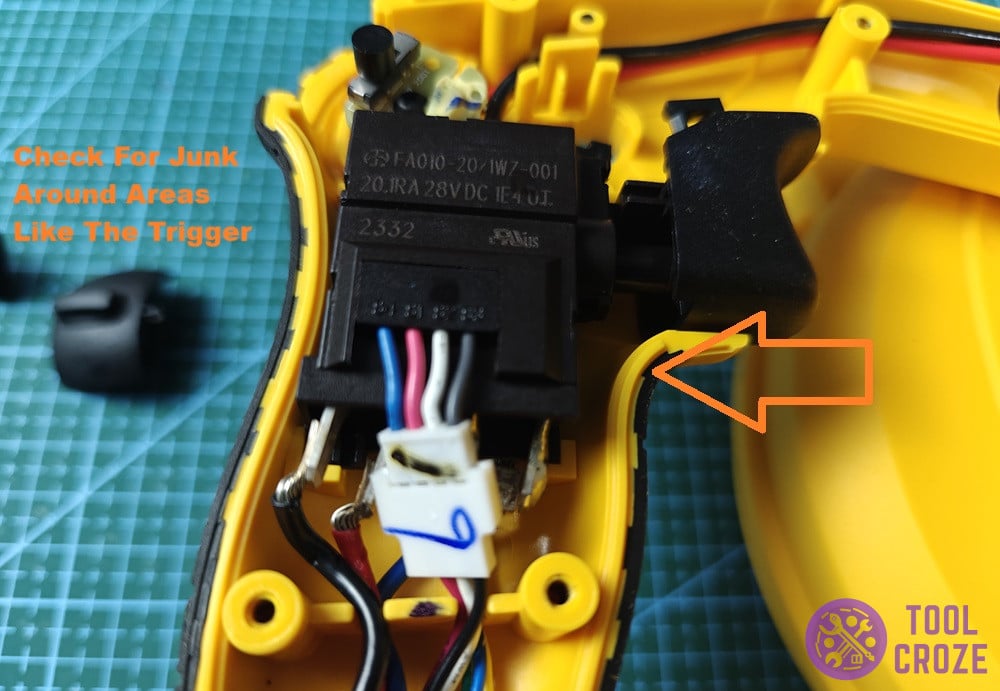

But, if you think your battery works fine and still has power, check the connections instead. If the contact points get dirty, that may ruin the connection between the battery and the DeWALT blower.

Gunk will get in the way and cut off the flow of power between both things. Cleaning the connection points every now and then will stop this from happening and ensure that your blower stays on.

Alternatively, it could be something more technical and internal. One big issue known for cutting out power is overheating. Blowers tend to overheat often because of the air generating inside them.

Prolonged use will make the tool overheat, which leads to the thermal protection cutting out and stopping it from working. If yours keeps cutting out, ensure it isn’t getting too hot during use.

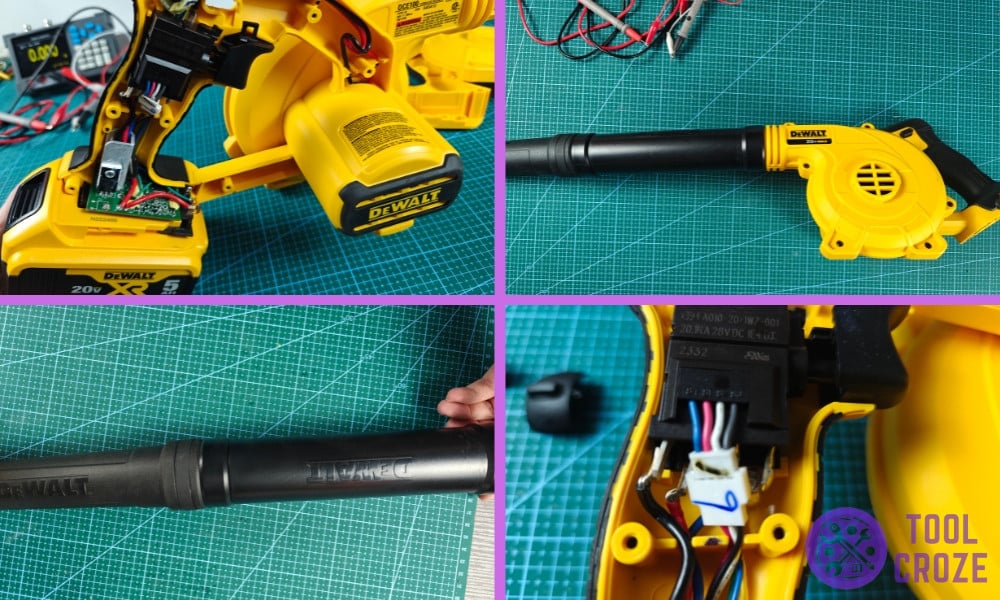

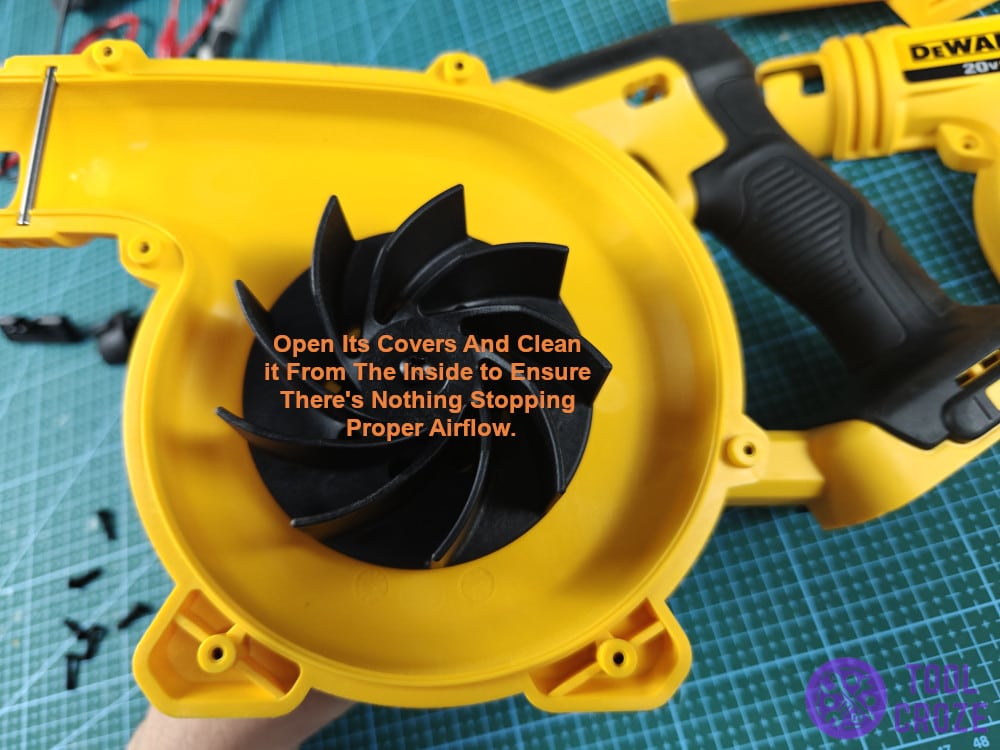

Debris inside the tool can make it overheat quicker. Open its covers and clean it from the inside to ensure there’s nothing stopping proper airflow, making it overheat quicker and stop working.

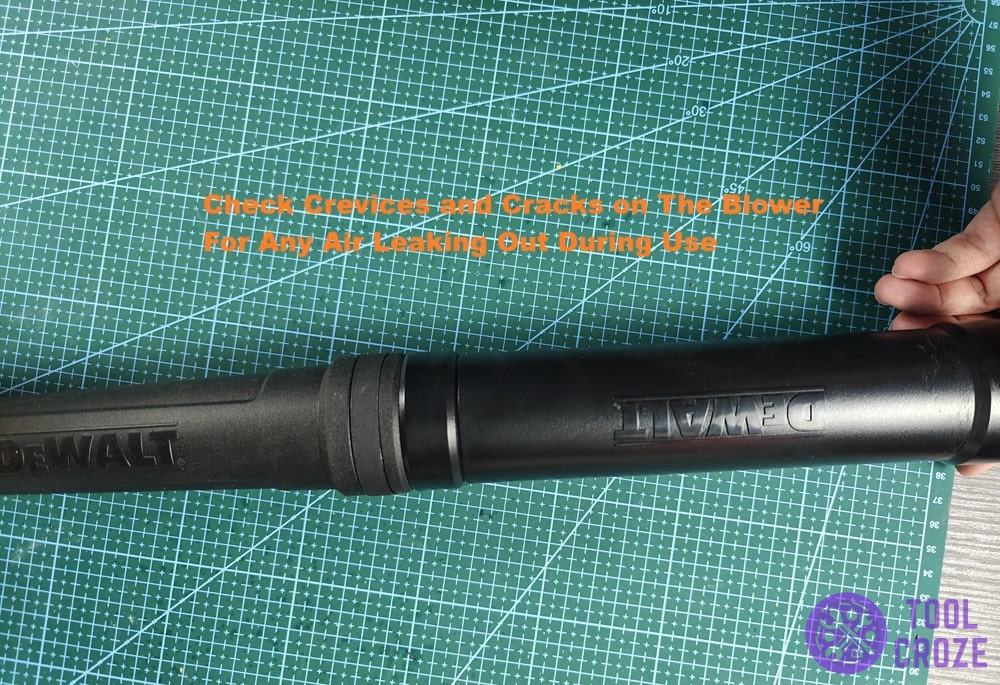

- Air Leaking From Blower

Pressure from the constant air flow nside a blower can damage its seals, especially around the motor. In short, there are gaps inside the tool that users will have to close off in order for air to stop leaking.

When running the DeWALT blower next time, I suggest finding the exact part air is leaking out of. It should be pretty easy to feel or hear the air leaking out of an exact spot.

Once you find out, check what exactly is causing air to leak out. You’ll find damage or chipping that’s leaving space for the air to come out. Repair this to stop that from happening any longer.

This usually only happens after a lot of time with the tool. It’s common, but only for users that have had their DeWALT blower for a very long time. The seals break down sooner or later, leading to this.

Repairing them requires the right replacement parts, but soldering the damaged area to prevent air from seeping out is also an option. While this isn’t as reliable, it’s certainly easier and less costly.

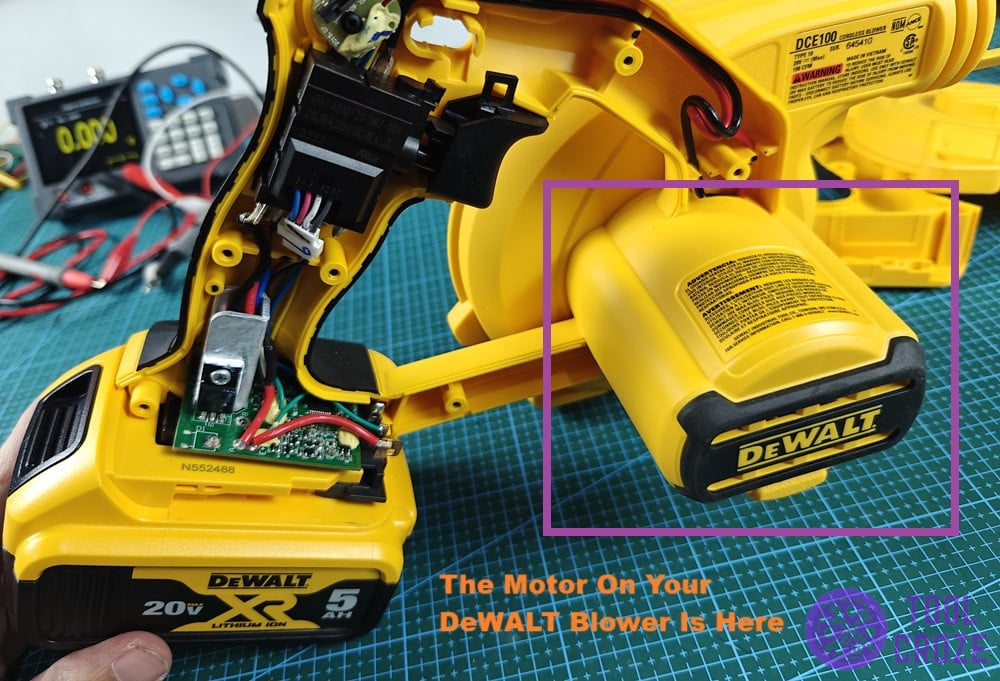

- Motor Problems

Have you ever used your DeWALT blower and found the air coming out of it to be “weaker” than usual?

Without a fully functioning motor, the output on the tool will be a lot lower. It won’t generate as much force as it normally would, leading to the current problem you’re facing.

Motors tend to get weaker with time, like all components do. That’s why this is yet another common problem, since it’s not possible to avoid after users spend long enough time with the blower.

Only way to confirm this is by checking the voltage on the motor of your DeWALT blower. For that, first step users will need to take is taking off the covers of their tool to expose the motor.

After having the motor in sight, the next step is connecting a multimeter to it. Multimeters will let you see exactly what the output on the motor is, and if it’s still good enough to power the tool.

Now, if the voltage doesn’t seem to match up with the tool’s specifications, that’s a sign that it’s no longer strong enough.

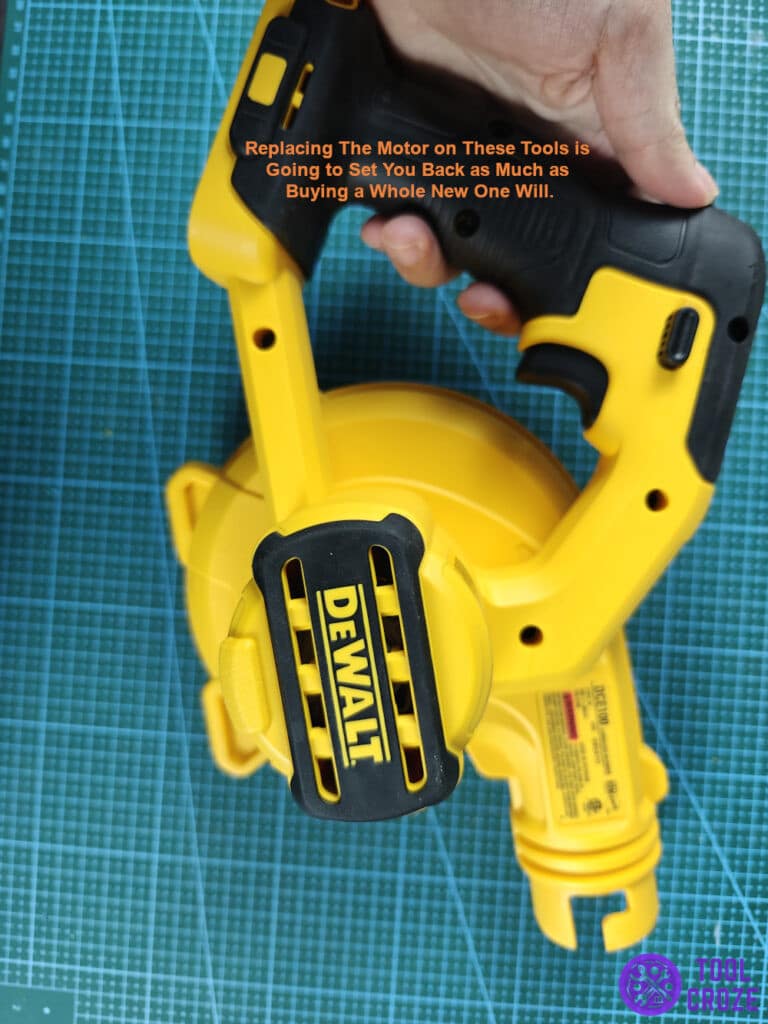

My opinion on fixing this? Well, I believe it’s best to get a new DeWALT blower once this happens. Replacing the motor on these tools is going to set you back as much as buying a whole new one will.

The smarter decision is to get a whole new blower. It won’t have any of the same problems, and will last a lot longer than a repaired model.

Thank you! Wish I’d read your article before I fought the new battery. The contacts were filthy, such a simple fix.